MAINTENANCE

3-31

285 MM191 (12---89)

DISTRIBUTOR (For machines below serial number

010750)

The distributor operation is vital to the operation of

the engine. The following items should be carefully

inspected after every 400 hours of normal operation;

however, dirt, dust, water, and high speed operation

may cause more rapid wear and necessitate more

frequent inspections:

1. Remove the distributor cap. Clean the cap and

examine for cracks, carbon runners, or

corroded terminals. If the vertical faces of the

inserts are burned, install a new cap. If the

horizontal faces of the inserts are burned,

replace the cap and the rotor as this condition

is caused by the rotor being too short. Inspect

cap to distributor seal and the distributor

housing breather.

2. Check the centrifugal advance mechanism for

“freeness” by turning the breaker cam in the

direction of rotation and then releasing it. The

advance springs should return the cam to its

original position.

ENGINE IGNITION TIMING (For machines below

serial number 010750)

The engine ignition timing must be checked with a

timing light, using the timing points located on the

front of the engine and the timing marks located on

the crankshaft pulley. Distributor ignition timing

should be checked after the first 50 hours of

operation and after every 400 hours of operation

thereafter.

To check and adjust the ignition timing with a scope,

refer to the scope manufacturer’s instructions. To

check and adjust the timing with a timing light,

proceed as follows:

TO CHECK AND ADJUST IGNITION TIMING (For

machines below serial number 010750)

NOTE: Dwell angle must be correct or timing will not

be accurate.

1. Stop the engine and set the machine parking

brake.

FOR SAFETY: Before leaving or servicing

machine; stop on level surface, set parking brake,

and turn off machine.

2. Clean and mark the timing marks.

NOTE: Painting a white line on the front pulley timing

marks will make them more visible under the timing

light.

3. Disconnect and plug the vacuum hose from the

distributor.

A

B

00696

ENGINE TIMING MARKS

A. Timing Pointer

B. Crankshaft Pulley

4. Connect the timing light to the No. 1 cylinder

spark plug wire. Connect a tachometer to the

engine.

WARNING: Keep away from fan.

5. Start the engine and reduce the idle speed to

600 rpm to be sure that the centrifugal advance

is not operating. Adjust the initial ignition timing

to 6

_

BTDC on gasoline engines, and 10

_

BTDC on LPG engines.

To advance the timing, turn the distributor body

clockwise. To retard the timing, turn the

distributor body counterclockwise.

6. Check the centrifugal advance for proper

operation by starting the engine and

accelerating it to approximately 2000 rpm. If the

ignition timing advances, the centrifugal

advance mechanism is functioning properly.

Note the engine speed when the advance

begins and the amount of total advance. Stop

the engine.

Содержание 285

Страница 1: ...r 285 Sweeper Scrubber ...

Страница 6: ...ABOUT THIS MANUAL 285 MM191 12 89 d ...

Страница 18: ...SPECIFICATIONS 285 MM191 12 89 1 2 ...

Страница 22: ...SPECIFICATIONS 285 MM191 12 89 1 6 ...

Страница 24: ...OPERATION 2 2 285 MM191 12 89 ...

Страница 62: ...OPERATION 2 40 285 MM191 NIL ...

Страница 76: ...MAINTENANCE 285 MM191 12 89 3 14 04644 HYDRAULIC SCHEMATIC LOW DUMP MODEL ...

Страница 77: ...MAINTENANCE 3 15 285 MM191 12 89 04645 HYDRAULIC SCHEMATIC MULTI LEVEL DUMP MODEL ...

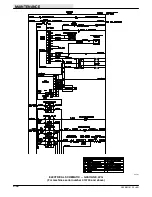

Страница 100: ...MAINTENANCE 285 MM191 6 90 3 38 04643 ELECTRICAL SCHEMATIC DIESEL For machines below serial number 010750 ...

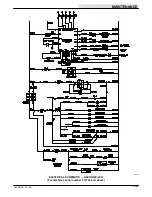

Страница 101: ...MAINTENANCE 3 39 285 MM191 6 90 06208 ELECTRICAL SCHEMATIC DIESEL For machines serial number 010750 and above ...

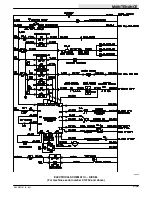

Страница 102: ...MAINTENANCE 285 MM191 6 90 3 40 06208 ELECTRICAL SCHEMATIC DIESEL For machines serial number 010750 and above ...

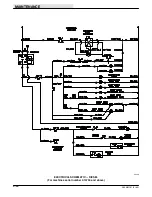

Страница 103: ...MAINTENANCE 3 41 285 MM191 6 90 06187 ELECTRICAL SCHEMATIC AUTO SHAKER RFS ...

Страница 104: ...MAINTENANCE 285 MM191 6 90 3 42 06187 ELECTRICAL SCHEMATIC AUTO SHAKER RFS ...

Страница 134: ...APPENDIX 285 MM191 12 89 4 2 ...