OPERATION

2-18

285 MM191 (12---89)

NORMAL SCRUBBING OPERATION

A normal scrubbing operation consists of seven

typical operations: pre-start checklist, starting

machine, scrubbing, draining recovery tank and

emptying hopper, post operation checklist --- engine

operating, stopping machine, and post operation

checklist --- engine stopped.

PRE-START CHECKLIST

lists things to check before

starting the machine.

TO START MACHINE

lists the steps required to start

the machine.

TO SCRUB

lists things to keep in mind before and

during the scrubbing operation.

TO DRAIN RECOVERY TANK AND EMPTY HOPPER

lists the steps required to empty the debris hopper

and the recovery tank.

POST OPERATION CHECKLIST --- ENGINE

OPERATING

lists things to check before stopping the

machine engine.

TO STOP MACHINE

lists the steps required to stop

the machine.

POST OPERATION CHECKLIST --- ENGINE STOPPED

lists things to check after stopping the machine

engine.

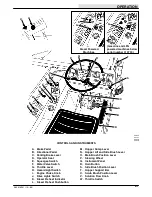

PRE-START CHECKLIST

Check under machine for leak spots.

Empty the engine air filter dust cap and check the air

filter restriction indicator.

Check the engine radiator for debris and clean if

needed.

Check the brushes and brush skirts for damage,

wear and adjustment.

Check engine lubricating oil level.

Check fuel level.

Check for LPG odor indicating a fuel leak.

Check brakes and controls for proper operation.

Check service records to determine service

requirements.

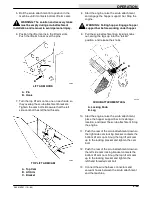

TO START MACHINE

NOTE: Before starting machine, perform the pre-start

checks.

1. LPG powered machines: Slowly open the liquid

service valve.

NOTE: Opening the service valve too quickly may

cause the service valve check valve to stop the flow

of LPG fuel. If the check valve stops the flow of fuel,

close the valve, wait a few seconds, and slowly open

the valve once again.

Diesel powered machines: Push the diesel

preheat pushbutton until the preheat indicator

glows brightly.

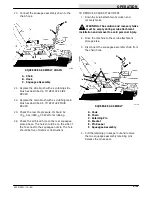

2. The machine operator must be in the

operator’s seat with the directional pedal in the

“neutral” position and with a foot on the brake

pedal or with the parking brake set.

FOR SAFETY: Before leaving or servicing the

machine; stop on level surface, set parking brake,

and turn off machine.

3. Gasoline powered machines: When the engine

is cold, pull out the choke knob about

three-fourths of the way. Push choke in after the

engine is running smoothly.

LPG powered machines: When the engine is

cold and exposed to cold temperatures, open

the engine cover, press the primer button on

the LPG vaporizer, close the engine cover.

4. Place throttle control in the (Idle) position.

5. Turn the ignition switch key clockwise. Press

the start switch until the engine starts. Do not

operate the starter for more than a few seconds

at a time or after the engine has started.

NOTE: Do not operate the starter motor for more than

10 seconds at a time or after the engine has started.

Allow the starter to cool between starting attempts.

The starter motor may be damaged if it is operated

incorrectly.

6. Allow the engine and hydraulic system to warm

up three to five minutes.

7. Disengage the machine parking brake.

8. Place the throttle control in the (Fast 1) position

and drive the machine to the solution filling site.

Содержание 285

Страница 1: ...r 285 Sweeper Scrubber ...

Страница 6: ...ABOUT THIS MANUAL 285 MM191 12 89 d ...

Страница 18: ...SPECIFICATIONS 285 MM191 12 89 1 2 ...

Страница 22: ...SPECIFICATIONS 285 MM191 12 89 1 6 ...

Страница 24: ...OPERATION 2 2 285 MM191 12 89 ...

Страница 62: ...OPERATION 2 40 285 MM191 NIL ...

Страница 76: ...MAINTENANCE 285 MM191 12 89 3 14 04644 HYDRAULIC SCHEMATIC LOW DUMP MODEL ...

Страница 77: ...MAINTENANCE 3 15 285 MM191 12 89 04645 HYDRAULIC SCHEMATIC MULTI LEVEL DUMP MODEL ...

Страница 100: ...MAINTENANCE 285 MM191 6 90 3 38 04643 ELECTRICAL SCHEMATIC DIESEL For machines below serial number 010750 ...

Страница 101: ...MAINTENANCE 3 39 285 MM191 6 90 06208 ELECTRICAL SCHEMATIC DIESEL For machines serial number 010750 and above ...

Страница 102: ...MAINTENANCE 285 MM191 6 90 3 40 06208 ELECTRICAL SCHEMATIC DIESEL For machines serial number 010750 and above ...

Страница 103: ...MAINTENANCE 3 41 285 MM191 6 90 06187 ELECTRICAL SCHEMATIC AUTO SHAKER RFS ...

Страница 104: ...MAINTENANCE 285 MM191 6 90 3 42 06187 ELECTRICAL SCHEMATIC AUTO SHAKER RFS ...

Страница 134: ...APPENDIX 285 MM191 12 89 4 2 ...