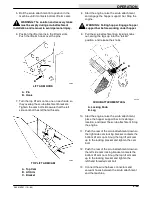

OPERATION

2-39

285 MM191 (12---89)

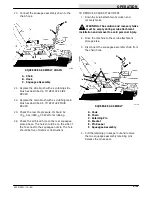

MACHINE STORAGE

STORING MACHINE

When storing the machine for extended periods of

time, these procedures must be followed to lessen

the chance of rust, sludge, and other undesirable

deposits from forming:

1. Empty the debris hopper.

2. Change engine oil.

3. Place the main brush and side brush position

levers in the “raise” position.

4. Park the machine on a level surface in a cool,

dry area.

5. Stop the engine and set the machine parking

brake.

6. Check the hydraulic fluid level. It should be up

to the full mark on the dipstick to prevent

excessive condensation from forming in the

reservoir.

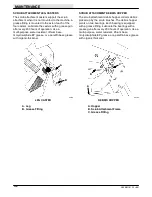

7A. Gasoline and LPG powered machines: To store

the machine 30 to 90 days:

1. Remove the spark plugs.

2. Pour 3 oz (90 cc) of clean engine oil into

each spark plug hole.

3. Remove the ignition coil high tension wire.

Operate the engine starter motor for at

least a dozen revolutions. This distributes

the oil over the cylinder walls.

NOTE: Before preparing the engine for storage, allow

it to cool down to the surrounding temperature. Oil

adheres to cold metal surfaces much better than hot

surfaces.

4. Replace the high tension coil wire and

spark plugs.

5. Drain the gasoline from the carburetor

bowl by removing the carburetor

anti-diesel solenoid.

6. Replace the carburetor drain plug.

7B. Gasoline and LPG powered machines: To store

the machine 90 days to 6 months:

1. Remove the spark plugs.

2. Pour 3 oz (90 cc) of clean engine oil into

each spark plug hole.

3. Remove the ignition coil high tension wire.

Operate the engine starter for at least a

dozen revolutions. This distributes the oil

over the cylinder walls.

NOTE: Before preparing the engine for storage, allow

it to cool down to the surrounding temperature. Oil

adheres to cold metal surfaces much better than hot

surfaces.

4. Replace the high tension coil wire and

spark plugs.

5. Drain the engine oil from the engine oil

pan.

6. Drain the coolant from the radiator and

engine block by opening the cooling

system drain cocks.

7. Close the engine cooling system drain

cocks.

8. Drain gasoline from the carburetor, fuel

tank, and the fuel lines.

9. Seal the air cleaner inlet and the exhaust

outlet with weatherproof masking tape.

10. Tighten the engine oil filler cap, the fuel

tank cap, and the radiator cap to make

certain they are securely in place.

7C. Diesel powered machines: To store machine:

1. Drain the coolant from the radiator and

engine block.

2. Close the engine cooling system drain

cocks.

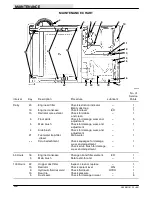

Содержание 285

Страница 1: ...r 285 Sweeper Scrubber ...

Страница 6: ...ABOUT THIS MANUAL 285 MM191 12 89 d ...

Страница 18: ...SPECIFICATIONS 285 MM191 12 89 1 2 ...

Страница 22: ...SPECIFICATIONS 285 MM191 12 89 1 6 ...

Страница 24: ...OPERATION 2 2 285 MM191 12 89 ...

Страница 62: ...OPERATION 2 40 285 MM191 NIL ...

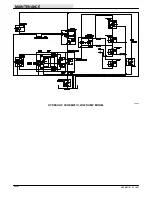

Страница 76: ...MAINTENANCE 285 MM191 12 89 3 14 04644 HYDRAULIC SCHEMATIC LOW DUMP MODEL ...

Страница 77: ...MAINTENANCE 3 15 285 MM191 12 89 04645 HYDRAULIC SCHEMATIC MULTI LEVEL DUMP MODEL ...

Страница 100: ...MAINTENANCE 285 MM191 6 90 3 38 04643 ELECTRICAL SCHEMATIC DIESEL For machines below serial number 010750 ...

Страница 101: ...MAINTENANCE 3 39 285 MM191 6 90 06208 ELECTRICAL SCHEMATIC DIESEL For machines serial number 010750 and above ...

Страница 102: ...MAINTENANCE 285 MM191 6 90 3 40 06208 ELECTRICAL SCHEMATIC DIESEL For machines serial number 010750 and above ...

Страница 103: ...MAINTENANCE 3 41 285 MM191 6 90 06187 ELECTRICAL SCHEMATIC AUTO SHAKER RFS ...

Страница 104: ...MAINTENANCE 285 MM191 6 90 3 42 06187 ELECTRICAL SCHEMATIC AUTO SHAKER RFS ...

Страница 134: ...APPENDIX 285 MM191 12 89 4 2 ...