2310/2330

2 _5 Maintenance / care

18

If in doubt about any safety matters con-

sult the manufacturer or their authorised

agency before putting the machine into

use.

2 _5.2 Cleaning the machine

Keep the bottom part of the machine in clean condition.

Clean or exchange floor pads.

2 _5.3 Guide roller

Clean guide roller regularly.

2 _5.4 Pad care

After using, clean coarse soiling from the pads, which

can be used on both sides, and replace the pads within

good time in order to achieve good cleaning results.

2 _5.5 Daily examination

•

Check mains cable for damage.

2 _5.6 Annual maintenance

An electrically-driven machine must be checked annu-

ally according to VDE-702 or comparable international

regulations.

This examination should be carried out by

a service technician who has been trained

by the manufacturer!

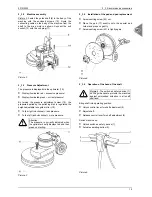

2 _5.7 Trouble shooting and fault eradication

Table 3

If the fault in the machine is not eradi-

cated after following the procedure ac-

cording to the above table, the manufac-

turer's customer service must be informed

and commissioned with the execution of

the necessary repair work.

Fault

Cause

Remedy

Maschine does not function

•

the main plug(6) is not correctly

inserted

•

the unit socket (12) is not

correctly inserted

•

Overload protection has

responded

•

ensure correct seating

•

ensure correct seating

•

Press overload protection switch (13)

knob in

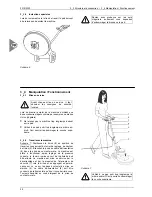

Machine shuts off after a short

while

•

Applied pressure incorrectly set

via optimeter

•

Adjust optimeter via adjustment screw

(19) (see Section 2 _3.3)

Machine runs in a jerky manner

•

soiled pad (17)

•

Pad unevenly worn

•

Guide roller defective

•

beat pad out / if necessary, wash out

under water

•

insert new pad

•

Inform service department

Optimeter in the red range after

a brief period of operation

•

Initial pressure in the pressure

adjustment screw (19) spring

insufficient

•

Replace spring