2310/2330

2 _3 Structure and accessories

15

2 _3.2 Machine assembly

Picture 2: Fasten the guide shaft (8) to the body of the

machine with the enclosed screws (10). Route the

connecting cable on the body of the machine from the

shaft to the drive motor as shown. Connect the unit

socket (12) with the unit plug (11).

Picture 2

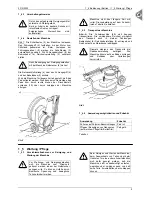

2 _3.3 Pressure Adjustment

The pressure is displayed via the optimeter (14):

•

Display illuminated red = excessive pressure!

•

Display illuminated green = correct pressure!

By turning the pressure adjustment screw (19), the

pressure applied by the polishing disk is regulated the

height-adjustable twin guide roller (18).

•

To the right (clockwise) = less pressure.

•

To the left (anti-clockwise) = more pressure.

Attention:

The pressure is correctly adjusted when

the optimeter briefly displays red and then

green on starting.

Picture 3

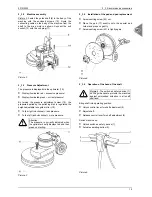

2 _3.4 Installation of the pad and pad replacement

•

Screw centring screw (22) out.

•

Place the pad (17) exactly onto the special pad

holder and press on gently.

•

Screw centring screw (22) in tightly again.

Picture 4

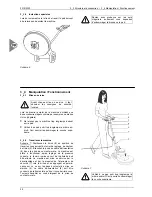

2 _3.5 Operation of the head of the shaft

Picture 5: The switch-on safety device (1)

on the guide handle protects the machine

against unintended actuation in all shaft

positions!

Bring shaft into operating position:

•

Unlock control lever for shaft adjustment (5),

•

Adjust shaft,

•

Release control lever for shaft adjustment (5).

Switch machine on:

•

Unlock switch-on safety device (1),

•

Actuate operating button (2).

Picture 5