5-12

Phaser 440 Color Printer

5

Theory of Operation

Printing

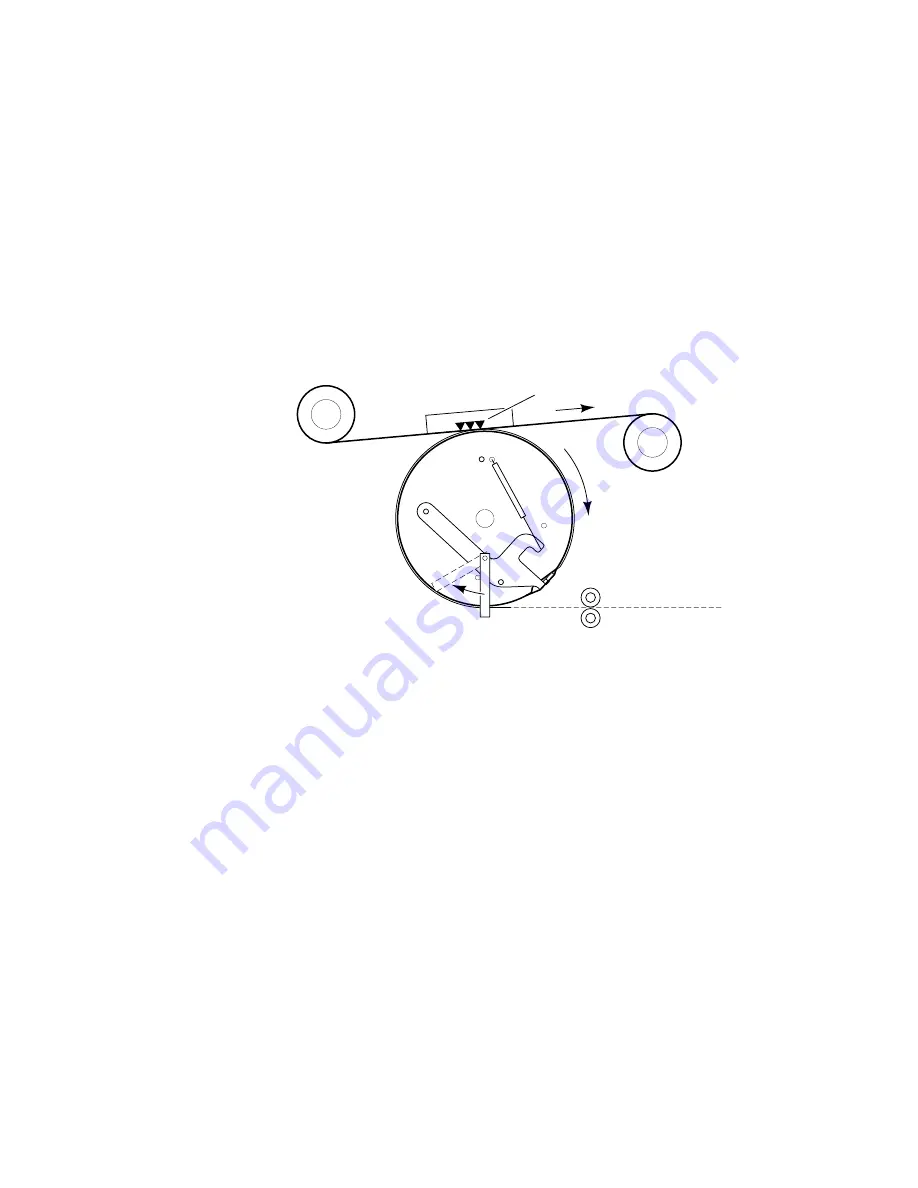

After checking the transfer roll's position (through the transfer roll mark

sensors) the thermal head lift motor rotates an eccentric cam to push the thermal

head down from its standby position to its print position, sandwiching the

transfer roll and paper together between the thermal head and the drum.

Printing begins as the drum slowly rotates forward (clockwise) drawing the

paper and the transfer roll past the thermal head where dye is vaporized from

the transfer roll onto the paper to form a printed image. Contact friction

between the moving paper and the transfer roll moves the transfer roll past the

thermal head at the same rate as the paper.

The sheet of paper is drawn past the thermal head three times to form a

complete image. When the first pass (yellow printing) is completed, the thermal

head lift motor raises the thermal head to its standby position allowing the

paper clamp to pass underneath. When the paper reaches the print-start

position, the thermal head lift motor rotates to bring the thermal head back to

the print position, and printing continues with magenta printing. This process

repeats again for cyan printing and black and then the print is ready to be

unloaded to the printer's output tray. (During forward rotation, the drum stops

are simply pushed out of the way. The drum stops can only open the clamp

during reverse drum rotation.)

Figure 5-7 Printing on the paper

8699-14A

Thermal head

Transfer

roll

Paper

Drum and

transfer roll

move at

same rate

Drum stops at

each end of the drum

pivot out of the way

Transfer roll

mark sensors