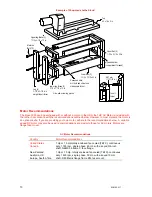

Spindle Index

The spindle index pin locks the

headstock spindle. It is selectable in

15 degree increments (24 divisions).

There is sight hole to read index

numbers (0 through 23).

1. Stop the lathe.

2. Pull the index knob and turn it left

until the pin drops into the hole. To

lock the spindle it must engage into

a hole in the headstock pulley.

!

Warning!

Make sure the index pin is

out before operating the lathe.

The pin should drop into the

indentation in the headstock to

prevent it from engaging while

the spindle is turning.

Pin

Sight Hole

Index Knob

Headstock

Spindle

Index pin shown

in safe (operation)

position

Divisions Index

Number

Degrees

2 0,12

180

3

0,8,16 (every 8

th

) 120

4

0,6,12,18 (every 6

th

) 90

6

0,4,8,12,16,20 (every 4

th

) 60

8 0,3,6,9,12,15,18,21 (every 3

rd

) 45

12

0,2,4,6,8…22 (every 2

nd

) 30

24 every

hole

15

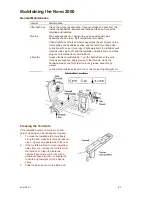

Headstock

The headstock houses the motor pulley, headstock pulley, bearings, and the spindle. The headstock

spindle accepts centers and accessories with no. 2 Morse taper (#2 MT), plus threaded faceplates and

chucks.

Spindle Thread Size

Country

Threads

United States, Canada, UK

1-1/4 x 8 TPI RH

Europe

M33 x 3.5 RH

Australia, New Zealand, South Africa

M30 x 3.5 RH

Mounting a faceplate or chuck

1. Use the spindle Index Pin to lock

the headstock spindle.

2. Screw the faceplate or chuck onto

the spindle threads. A spindle

washer in-between may be used to

make removal easier.

!

Warning!

The faceplate or chuck body

must contact the shoulder on

the spindle bearing.

3. Pull and turn the Index Pin and

place it in the "safe" indentation in

the headstock.

Faceplate

Index Pin

Headstock

Spindle

Faceplate or chuck body

must contact shoulder on

the spindle bearing.

!

18

92-0106-017