5.

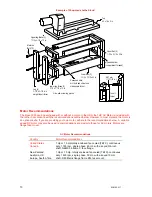

For Flange Mounted Motor Only.

Screw the motor mount plate to the

motor using four flathead Allen screws

(M6x20 Metric or 3/8 x 1 for

USA/Canada). If the motor has an

integral on/off switch, make sure the

motor is oriented for access to the

switch.

L

Note: In the USA, the

Motor is sometimes supplied with the

lathe - the motor needs to be mounted

so that the switch is on the top for easy

access.

Flange Mounted Motor

Motor

Motor

Mount Plate

Flathead

Screws (4)

L

Note: The foot mounting rail kit is an

option not included with the

standard lathe.

6.

For Foot Mounted Motor Only. Screw

the mounting rails to the motor mount

plate using four M8 bolts and washers.

Then attach the motor to the rails using

four M8 bolts, nuts, and washers.

Adjust the position of the motor on the

rails after the pulley is attached (steps

7-10). Then tighten the bolts to firmly

secure the motor to the rails.

Foot Mounted Motor

Motor

Motor

Mount Plate

Bolts (4)

Rails

Bolts (4)

Foot

Mounting

Rail Kit

(optional)

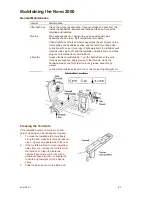

7.

Fit the key into the motor shaft keyway.

Align the keyway in the motor pulley to

the motor shaft and slide the pulley

onto the motor shaft. Leave about 13

mm (1/2-inch) between the pulley and

motor. Loosely secure the pulley to

the shaft with a M8x10 set screw with

an Allen wrench.

L

Note:The motor pulley is available with a

5/8-inch bore (US, Canada) or a 19

mm bore (NZ, Australia, Europe,

South Africa). Make sure the motor

pulley bore is correct for the motor

shaft. (The 19 mm pulley has a ring

on the boss at the key end to aid

identification).

Installing the Motor Pulley

Set Screw

Key

Motor Shaft

Motor Pulley

Allen

Wrench

8. Place the extra M12 washer (not illustrated) supplied in the Flange kit over the rear Headstock

stud.

9. Place the motor mount plate with attached motor over both the Headstock studs.

10. Place the headstock guard on the headstock; part of it slips between the motor mount plate and

the motor pulley. The extra M12 washer mentioned in step 8 should be on the Flange side on the

guard. Attach the guard to the headstock with five M5x10 screws. Tighten the screws after the

guard has been correctly positioned.

11. Install a M12 washer and M12 Nyloc nut on the lower (pivoting) headstock stud. Tighten the nut

until the motor mount plate is secure, but movable.

12. Place the motor mount cam over the upper (cam) headstock stud. Install a M12 washer and M12

Nyloc nut. Tighten the nut until smooth sliding action is achieved. Screw the Teebar into the

cam.

12

92-0106-017