Maintenance (Continued)

2. Follow steps 1 through 5 under

“Cleaning/Replacing Impeller.”

3. Remove rotating half of seal by

placing two screwdrivers under seal

plate and carefully prying up (Figure

15). Seal plate will slide off shaft,

bringing seal with it.

IMPORTANT:

Be sure you do not

scratch or mar shaft; if shaft is marred,

it must be dressed smooth with fine

emery or crocus cloth before installing

new seal. DO NOT reduce shaft

diameter.

4. Place seal plate face down on flat

surface and tap out stationary half

of seal.

IMPORTANT:

Be sure you tap on the

ceramic seat, not on copper heat sink.

Do not disturb heat sink (Ref. No. 4,

Figure 29).

INSTALLING NEW SEAL

1. Clean seal cavity in copper heat sink.

Do not disturb heat sink. (If heat

sink is moved or dislodged, see

instructions for “Copper Heat Sink

Installation,” Page 12.

2. Wet outer edge of O-Ring on

ceramic seat with liquid soap. Be

sparing!

3. Put clean cardboard washer on seal

face. Polished face of ceramic seat

should be up. With thumb pressure,

press ceramic seal half firmly and

squarely into seal cavity in copper

heat sink (See Figure 16). If seal will

not seat correctly, remove, placing

seal face up on bench. Reclean

cavity. Seal should now seat

correctly.

4. If seal does not seat correctly after

recleaning cavity, place a cardboard

washer over polished seal face and

carefully press into place using a

piece of standard 3/4” pipe as a

press.

IMPORTANT:

Be sure you do not

scratch seal face.

5. Dispose of cardboard washer and

recheck seal face to be sure it is free

of dirt, foreign particles, scratches,

and grease.

6. Inspect shaft to be sure it is free of

nicks and scratches.

7. Reassemble seal plate to motor

flange. BE SURE it is right side up:

index pins should be down; seal

plate is marked at top (See Figures

17 and 18).

8. Apply liquid soap sparingly (one

drop is sufficient) to inside diameter

of rotating seal member.

9. Slide rotating seal member (carbon

face first) onto shaft until rubber

drive ring hits shaft shoulder.

IMPORTANT:

Be sure not to nick or

scratch carbon face of seal when

passing it over threaded shaft end and

shaft shoulder (See Figure 19). The

carbon surface must remain clean or

short seal life will result.

Models 3P683D, 3P684D, 2P899A and 3P715B

11

Teel Operating Instructions and Parts Manual

®

E

N

G

L

I

S

H

506 0194

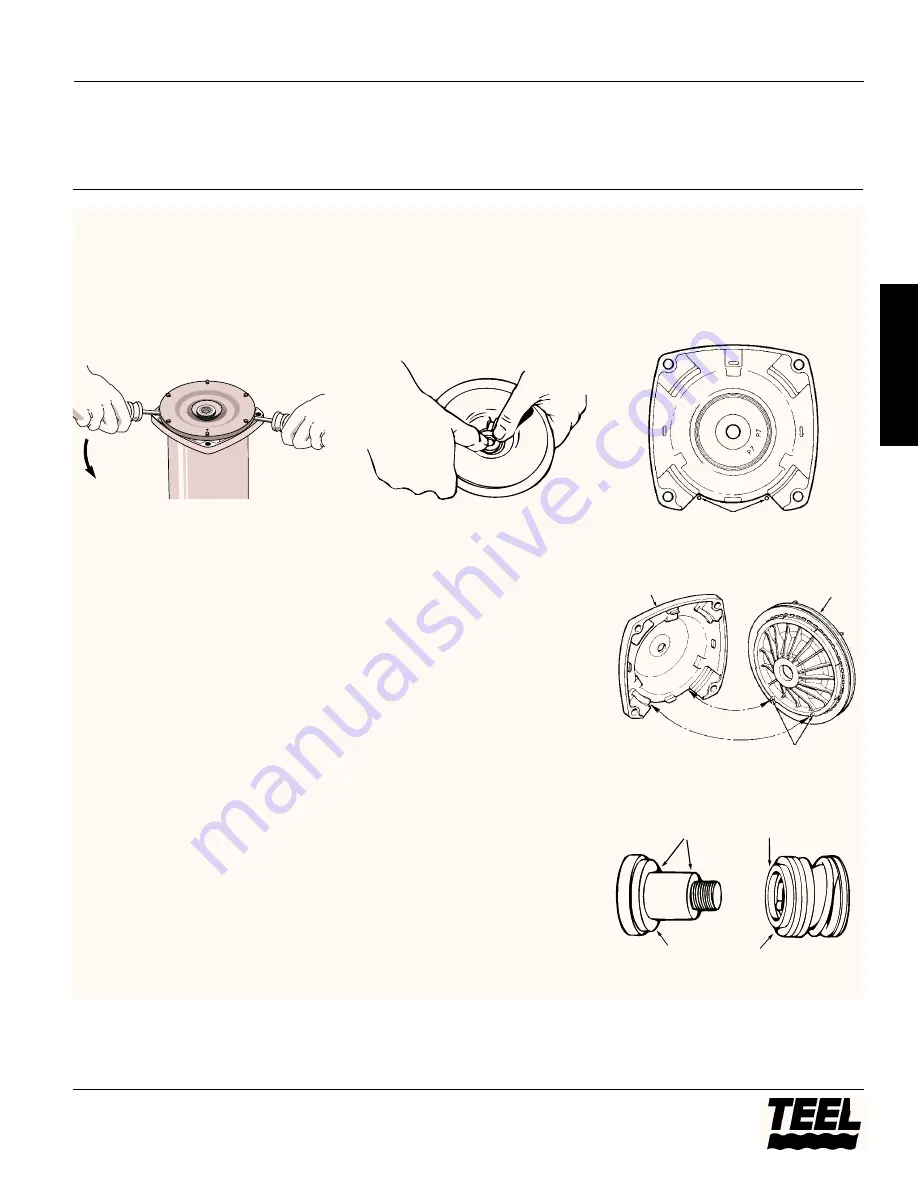

Figure 15 – Pry Off Seal PLate

Figure 16 – Press In Seal

Figure 17 – Locate Seal Plate on Motor

Flange

Top of motor flange

Seal plate index pins slide in here

Figure 19 – Do Not Nick Seal On Shaft

Shoulder

Figure 18 – Locate Seal Plate On Motor

Flange

Motor flange

Seal plate

Index pins

Ceramic face

Be careful that

shaft shoulder. . . . . does not damage

seal faces

Carbon face