INSTALLATION AND SETTING INSTRUCTIONS

- 23 -

The table below shows indicative information about the gas burner pre-adjustment:

Functioning of the burner at its

MAX.

nominal thermal

IMPUT

:

DESCRIPTION

UNIT

TYPE 1

TYPE 2

Brand

RIELLO

RIELLO

Model

mod

BS 3/M

RS 34/M MZ

Position of combustion head

notch

2

1

Position of air shutter

notch

65

80

G20 methane gas (when supplied)

mbar

20

20

Gas pressure to the hose

mbar

7,4

7,0

CO2

%

10

10

Functioning of the burner at its

MIN.

nominal thermal

IMPUT

:

DESCRIPTION

UNIT

TYPE 1

TYPE 2

Brand

RIELLO

RIELLO

Model

mod

BS 3/M

RS 34/M MZ

Position of combustion head

notch

2

1

Position of air shutter

notch

15

20

G20 methane gas (when supplied)

mbar

20

20

Gas pressure to the hose

mbar

1,8

0,8

CO2

%

10

10

THE PRE-CALIBRATION VALUES ARE MERELY INDICATIVE AND NOT BINDING.

THE BURNER MUST BE CAREFULLY CHECKED AND ADJUSTED DURING FIRST START-UP PHASE.

BESIDES, THE COMBUSTION AIR PRESSURE SWITCH MUST BE CALIBRATED, IN ORDER TO

AVOID UNHEALTHY COMBUSTION.

The gas burner assembly, adjustment, and electric connectio

n fall within the installer’

s province and

responsibility.

Said operations must be carried out only by skilled and competent technical personnel who perform the work

by scrupulously adhering to the instructions mentioned in the burner and supply ramp manuals which are

delivered with the purchase.

If it is necessary to connect the equipment to a different kind of burners, you are kindly

requested to contact the Manufacturer who shall provide you with an updated list of other

brands and models certified for such connection.

Never install burners not bearing the EC mark and not included in the list of those that can be

connected to the air treatment unit.

Never install burners not bearing the EC mark and not included in the list of those that can be

connected to the air treatment unit.

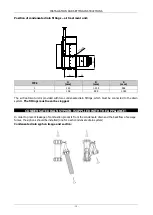

AIR OUTLET TEMPERATURE CONTROL PROBE

The electrical panel has a temperature probe placed at the ambient to be calibrated, or on the recirculation

air outlet duct. A shielded cable can be used to increase the length.

WARNING!

The temperature probe should be installed in an area having a non-turbulent air flow and not subjected to

radiation.

Содержание WIMBLEDON 145

Страница 26: ...INSTALLATION AND SETTING INSTRUCTIONS 26 WIRING DIAGRAM Cod 10023495 TC Wiring diagram TYPE 1...

Страница 27: ...INSTALLATION AND SETTING INSTRUCTIONS 27...

Страница 28: ...INSTALLATION AND SETTING INSTRUCTIONS 28 Wiring diagram TYPE 2...

Страница 29: ...INSTALLATION AND SETTING INSTRUCTIONS 29...

Страница 39: ...TECHNICAL ASSISTANCE INSTRUCTIONS 39 NOTES...