12

Call: 1-631-648-7481 or Visit: support.technocnc.com

13

HD II Tabletop Manual

NK105G2

Call: 1-631-648-7481 or Visit: support.technocnc.com

HD II Tabletop Manual

NK105G2

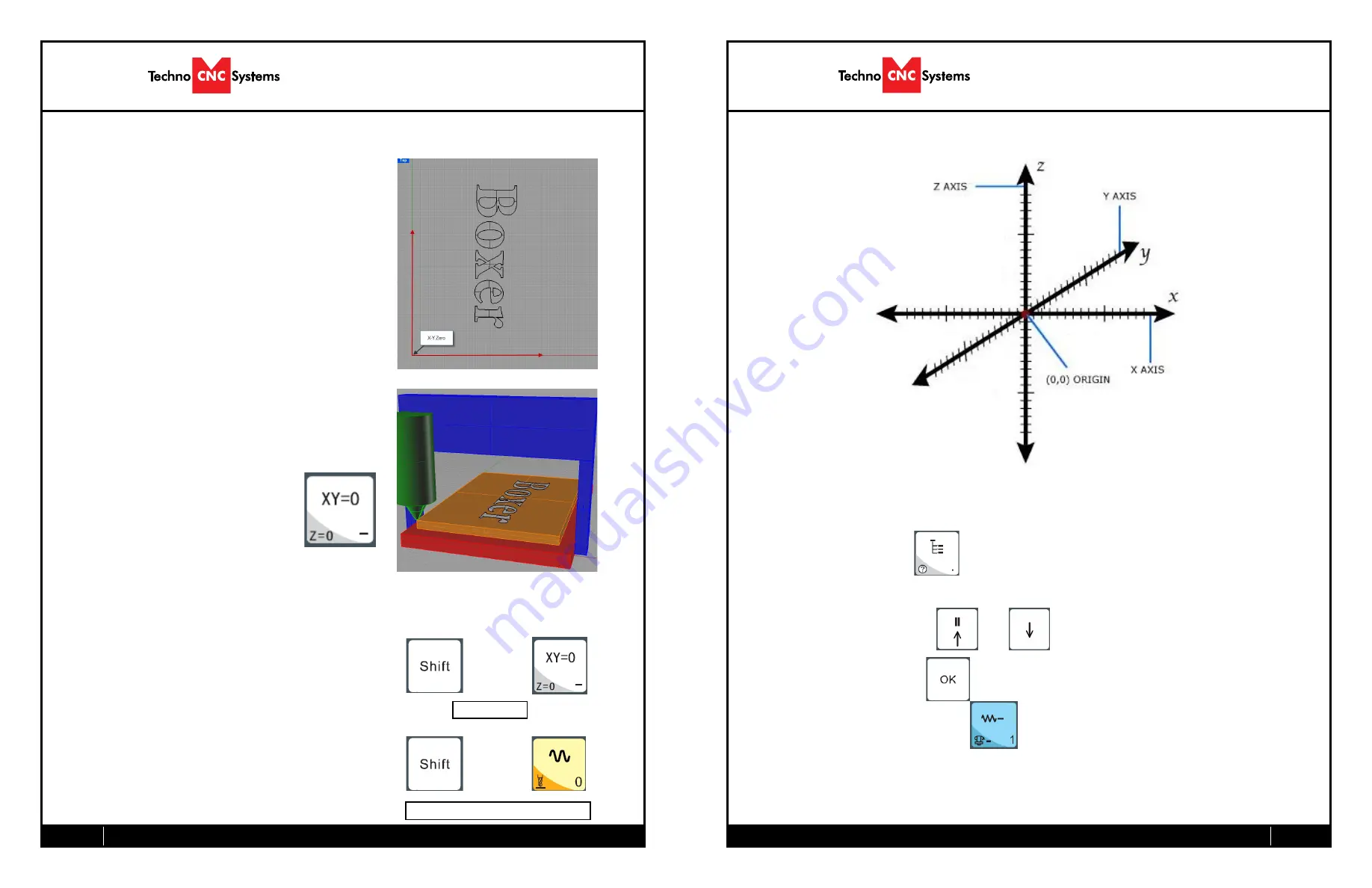

3.5- Adjusting the XYZ Zero position/WCS/User Origin.

XYZ zero position, Working Coordinate System (WCS), and

User Origin are all the same thing.

Different CAM systems and users just name the concept

differently. For convenience XYZ zero position will be used in

the rest of this manual.

XYZ zero position is the location point on a drawing in a

CAD/CAM package where X,Y and Z all equal zero.

Generally, XY zero is on the bottom left corner and Z zero

is the top of the part. In fig 3.3a the letters are located

away from the XY zero, all points representing positive

integers.

In Fig 3.3b the object represents the material the letters will

be cut from. The machine should be jogged to the corner of

the material by using the directional arrows on the keypad.

Once the machine is in location press to set XY zero. The

coordinates on the controller will change to 0,0.XY zero is

now set.

Fig.3.3b

Fig. 3.3a

There are two methods for setting the Z-axis zero position:

1. Manual Method: Use the Z-axis directional arrows on the

keypad to move the router to the top of the material. Switch

to Step Mode to slowly move the machine into position.

When the router bit is in position press shift/aux and the

Z=0 button as shown.

2. Tool Calibration Block: Place the touch off block on top

of the material and under the cutter. Press shift/aux and 0

simultaneously. The spindle will slowly move down until it

touches the touchpad. The Z axis will now be set to the top

of the material.

The Z coordinate will now read ‘Z 0.000’

+

Zero Z-axis

Activate Z-Touch off procedure.

+

3.6- Loading a G-code

File.

Press the Menu button.

Select “2.USB files” to access the flash drive.

Only a G-code file with an “nc” extension with show.

Scroll through the files with

and

Select file by pressing OK.

Then load the file by pressing 1.

Note:

Files can be copied from this USB to the controller using the “2” button

Local disk space is limited!

Once a file is copied locally, it can also be selected from the jog speed /step size screen