10

Call: 1-631-648-7481 or Visit: support.technocnc.com

11

HD II Tabletop Manual

NK105G2

Call: 1-631-648-7481 or Visit: support.technocnc.com

HD II Tabletop Manual

NK105G2

Select between high and

low Jog speeds

3.1- Jogging the machine and changing from High/Low Jog Speed.

To Jog the machine, hold down one of the Yellow directional keys on the keypad

while in Jog mode. The keypad has X+,X-,Y+,Y-,Z+,Z- printed on the keys to

indicate direction.

The machine has two speeds, High and Low.

When the machine starts it will be in the Low speed.

To toggle between low and high speed press the Jog Speed Select Button. You can

only toggle speed when in Jog Mode.

The LCD will display High or Low on the right of the screen.

Press ‘OK’ to change high and low speeds, see section 3.3.

III Operating Tutorials.

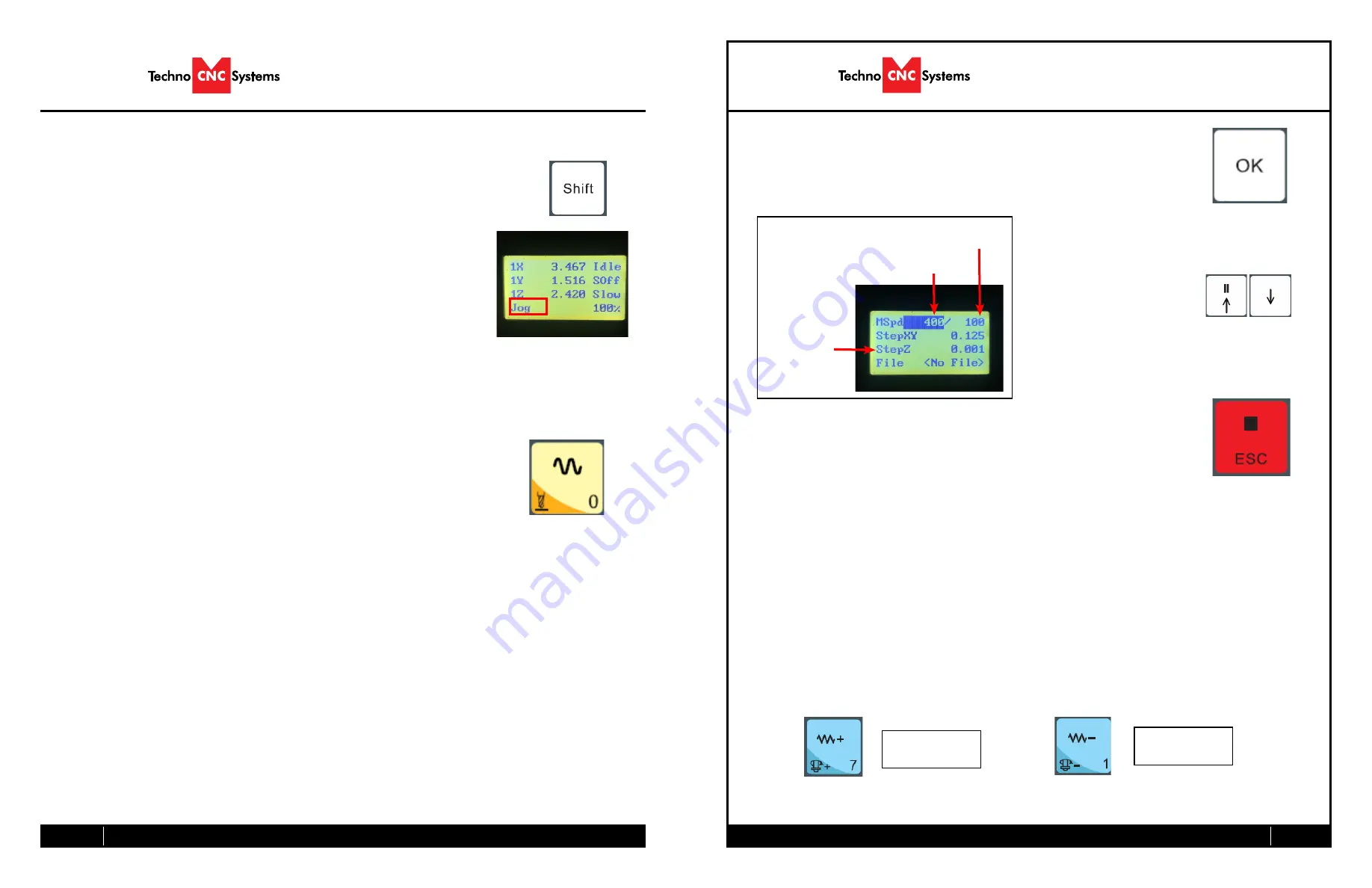

3.0- Switching Movement to Step or Jog.

There are two modes that allow the user to control the movement of the

machine: Jog and Step. To switch between these modes press the “Shift” button.

The mode will be displayed on the bottom left of the screen.

Jog- Also known as continuous mode. When a directional arrow is pressed, the

machine will move in that direction until the button is released.

Stepping- Also known as step mode. When a directional arrow is pressed, the

machine will move an exact amount, as dictated by the manual parameters

page. To move again, you must release the button and press it again.

3.2- Stepping the machine.

To move the machine in increments, press down one of the Yellow directional keys on the

keypad while in Stepping mode. The keypad has X+,X-,Y+,Y-,Z+,Z- printed on the keys to

indicate direction.

This will move the machine in predetermined increments in the axis selected.

By default, the X and Y axes will move in .005 inches and the Z axis will move in .001

inches.

Press ‘OK’ to change step size, see section 3.3

Decrease

Feedrate

Increase

Feedrate

OR

3.3- Modifying the Jog Speed and Step Size

The machine can be jogged at two speeds, low and high. You can also change the

increments in which the machine will move in Step mode. These speeds are set in

the Manual Parameters page.

To access the Manual Parameters page press OK from the Main Screen

Set the High and Low speed to a suitable value.

Adjust the Step value as needed.

To Exit out of this screen and return to the main menu press ESC.

Warning: Adjust the step size carefully. If you set the step size to an excessive value, the

machine will move by that value and could damage the machine.

When inputting a decimal increment, you must enter the value as 0.###

Zero+(your increment)

Low Speed

High Speed

XY Step Size

To move the cursor, use the Up and Down directional

arrows.

Enter a new value.

Press OK to accept that value.

3.4- Feedrate Override.

While running a G-Code file, the user can manually override the feedrate or

cutting speed of the program. The range of the override goes from 10% to 120%

of the original feedrate.

The user can override the feedrate using the following keys: