3. DISASSEMBLY

AND

REASSEMBLY

EO18-13004

3.4 Reassembly Procedure

3-12

3.4 Reassembly Procedure

Reassemble each part in the reverse order of the disassembly procedure described in Sections 3.2

and 3.3.

3.5 Lubrication

Apply specified lubricant to the specified locations.

3.5.1 Lubricant

Grease: Molykote EM-10L

3.5.2 Where to Lubricate

A. Sliding surface of the brake disk Refer to Section 3.3.1 Removing the Top Chassis SA.

B. Platen bushings and the platen shafts (2 locations each) Refer to Section 3.3.2 Removing the

Platen SA.

C. Gear shafts of the gear holder (2 locations) Refer to Section 3.3.4 Removing the Gear.

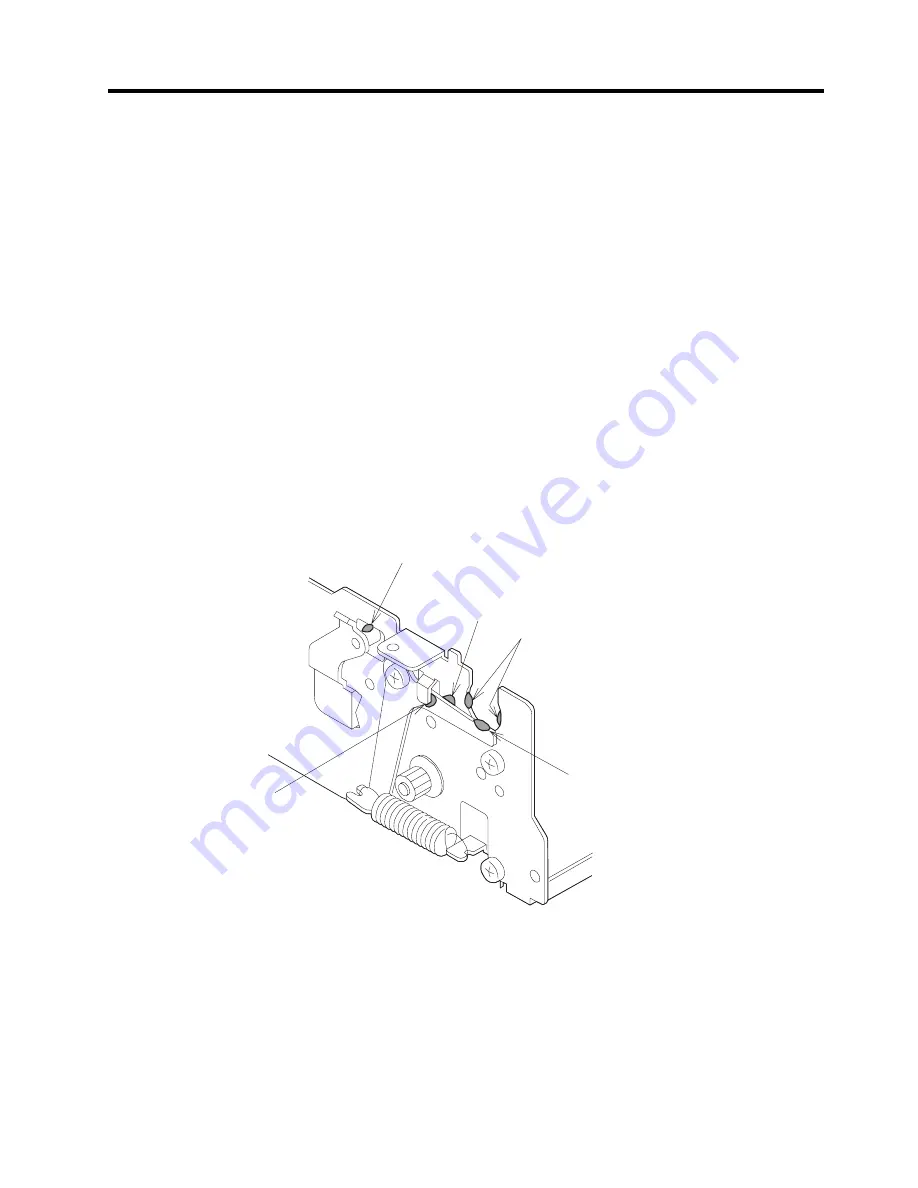

D. Shafts of the lock lever-R/L (2 locations on both sides)

E. Portions of the pressure arm-R/L which contact with other parts (3 locations on both sides)

F. U-shaped grooves of the main chassis, where the platen bushings are placed. (2 locations on

both sides)

D

E

E

E

F

Fig. 3-22