3 2

traction. With a longer link, the truck can start to drive more square, or point-to-point. This can make it difficult to carve corners

at high speed. A shorter rear camber link will generally result in more steering from the rear of the truck due to increased chassis

roll. This can make it easier to change directions quicker, but can cause the rear of the truck to roll around if the link is too short.

A shorter rear link will usually go through bumps a bit better than a long link as well.

Front Carrier Camber Location

is another adjustment that is almost always run in the standard (middle hole) location. This

location keeps the truck flatter with less roll. The middle location also helps the truck stay tighter in turns with a more precise

steering feel. Moving the link to the inner hole will make the steering react slightly slower. The advantage to the inner hole is that

it can increase on-power steering and help the truck get through bumps better. Moving the link to the outside hole will result in

more off power steering and will make the steering react faster.

Washers Under the Front Camber Link Ball Stud

can be added or removed. This is a very important adjustment on the

Triple-XT

truck. You should get a feel for how the number of washers affects the handling. Adding washers will make the truck

more stable and keep the front end flatter. Adding washers will give the truck more steering entering the turn but less steering on

the exit of the turn. Removing washers will reduce steering going into the turn and give more steering on the exit of the turn.

Front Camber Link Length

is another adjustment that is difficult to make a generic statement for as it can have slightly

different results on various conditions. The following is a summary of how this adjustment will usually impact the handling of the

Triple-XT

. A longer front camber link will usually make the truck feel stiffer. This will help keep the truck flatter with less roll, but

can make the truck handle worse in bumpy conditions. A shorter front camber link will result in more front end roll. This will

increase high-speed steering and make the truck better in bumps. Too short of a front link may make the truck feel twitchy or

"wandery" — meaning that it may be difficult to drive straight at high speed.

Front Shock Location

can be adjusted easily by simply moving top of the shock to another hole in the shock tower. The standard

location (second hole out) works best on most tracks. Moving the top of the shock out one hole will result in an increase in steering

and the truck will react quicker. Moving the top of the shock to the inside hole in the tower will slow the steering response time and

make the truck smoother in bumps.

The bottom of the shock can also be moved in and out on the suspension arm. Moving the shocks to the inside hole will result

in more low speed steering and less high speed steering. A stiffer spring should be used when using the inside hole. Moving the

shocks to the outside hole will require less shock limiters and will give more high speed steering and less low speed steering.

Rear Shock Location

can be changed just as easily as the front. Again, the standard location is the best place to start for most

tracks. Moving the top of the shock in on the shock tower results in less side-bite (traction in corners) and makes the truck

smoother in bumps. Moving the top of the shocks to one of the two outside holes will give the truck more forward traction and

side-bite and helps keep the truck from bottoming out on big jumps. A softer spring should be used if the shocks are mounted in one

of the two outer holes in the tower.

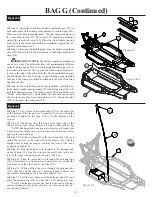

Rear Anti-Squat

is one of the two most commonly-used adjustments of the

Triple-XT

— washers under the front camber link

ball stud being the other. The

Triple-XT

, as built per assembly instructions, has 2

o

of anti-squat. Adding the shims under the front

of the pivot block will result in 4

o

of anti-squat. This will result in less side-bite, which will cause the truck to have more steering

from the rear end. More anti-squat will also make the truck get more air off of large jumps. Rear anti-squat is another adjustment

that you should play with to get a feel for the different handling characteristics.

Rear Hub Spacing

can be adjusted by moving the spacers at the front and rear of the hub carrier. You will probably find that the

middle (standard) location works best on just about every track. Spacing the hub back might help on large, high-speed, outdoor

tracks. Spacing the hub forward might help on tight, indoor tracks.

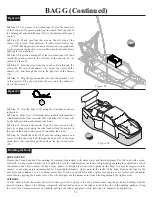

Battery Location

is sometimes overlooked, but can be a useful adjustment. Start by running the battery spaced in the middle.

Moving the battery back can improve rear traction on slippery tracks. Moving the battery back too far can cause the rear end to

swing though turns on some tracks. This is a result of having the weight too far back.

We are sure that you will find the

Triple-XT

to be the most versatile and easiest truck to drive fast with great consistency. We at

Team Losi hope this information helps you to enjoy your

Triple-XT

and racing as much as we do. Results may vary from track to

track. For the latest in setup information, visit the Team Losi website at:

www.TeamLosi.com

Содержание XXX-T Matt Francis Edition

Страница 2: ......