NOTE

i

409-10064

13 of 26

Rev B

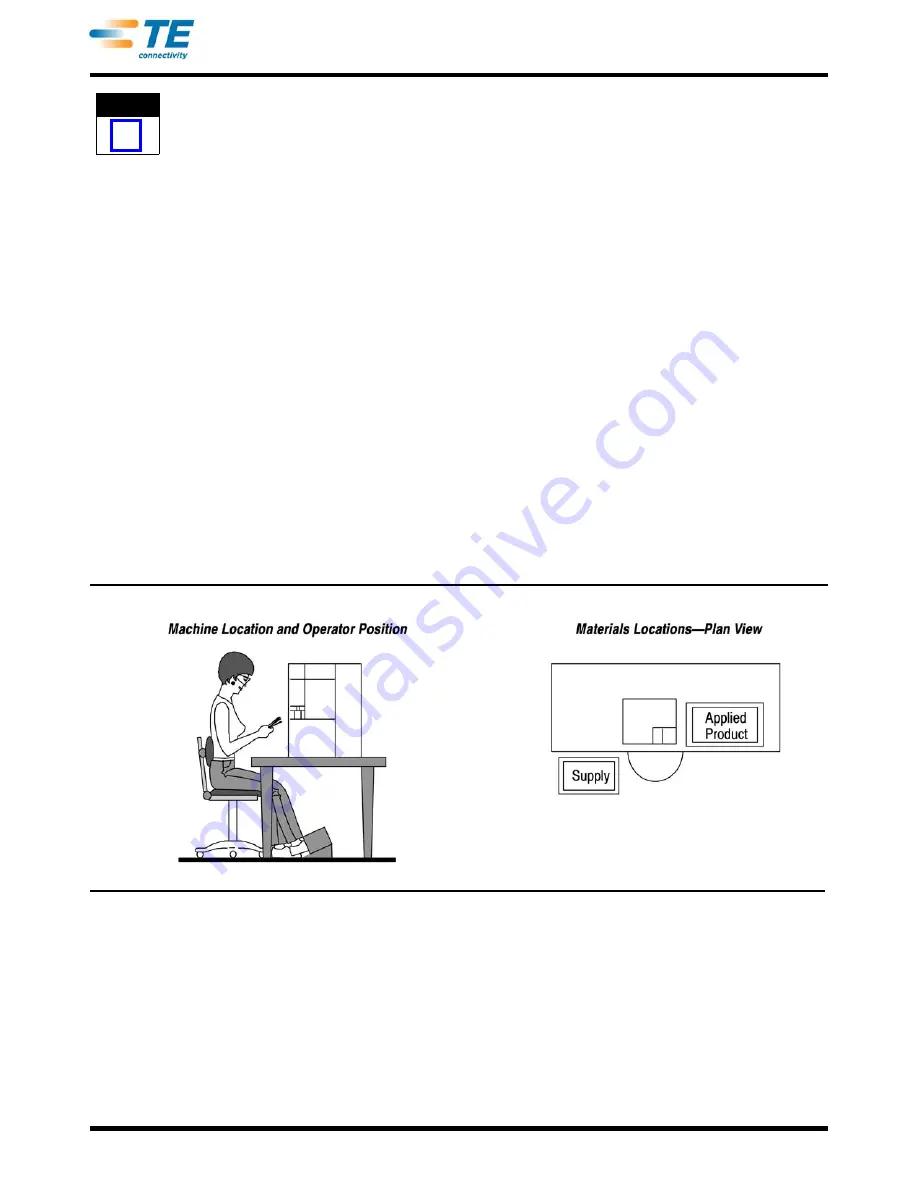

Machines have provisions for being bolted to the bench.

C. Operator's Chair

The operator's chair should swivel, and should have independent seat height and back rest adjustments. The

seat and back rest should be padded, and the back rest should be large enough to provide support both

above and below the waist line.

In use, the chair should be far enough under the bench so that the operator's back is straight and is supported

by the back rest.

D. Foot Switch

When the operator is correctly positioned in front of a machine equipped with a foot switch, the foot should

rest on the switch comfortably. The foot switch should be movable, so that its location can be readily changed

when the operator shifts position to minimize fatigue. Placing the switch on a rubber mat keeps it movable

while preventing unintentional sliding.

The preferred foot switch location varies to some extent among operators. Some operators prefer the switch

located so that their foot rests on the switch when their feet are in the natural sitting position (calf of leg

perpendicular to the foot). Others prefer the leg to be slightly in front of the natural position. The important

thing to remember is that the foot should be at approximately 90_ (right angle) to the calf when resting on the

switch. Those operators who prefer the foot switch slightly in front of the natural position may require a

wedge-shaped block placed under it.

E. Scrap Removal

A scrap bin is provided with the DCC terminator to capture the scrap chips.

Figure 8

Содержание 1804150-1

Страница 15: ...409 10064 15 of 26 Rev B Figure 10 Cont d...