Section 5

5-1

Model 104

User Interface

5

User Interface

User Interface

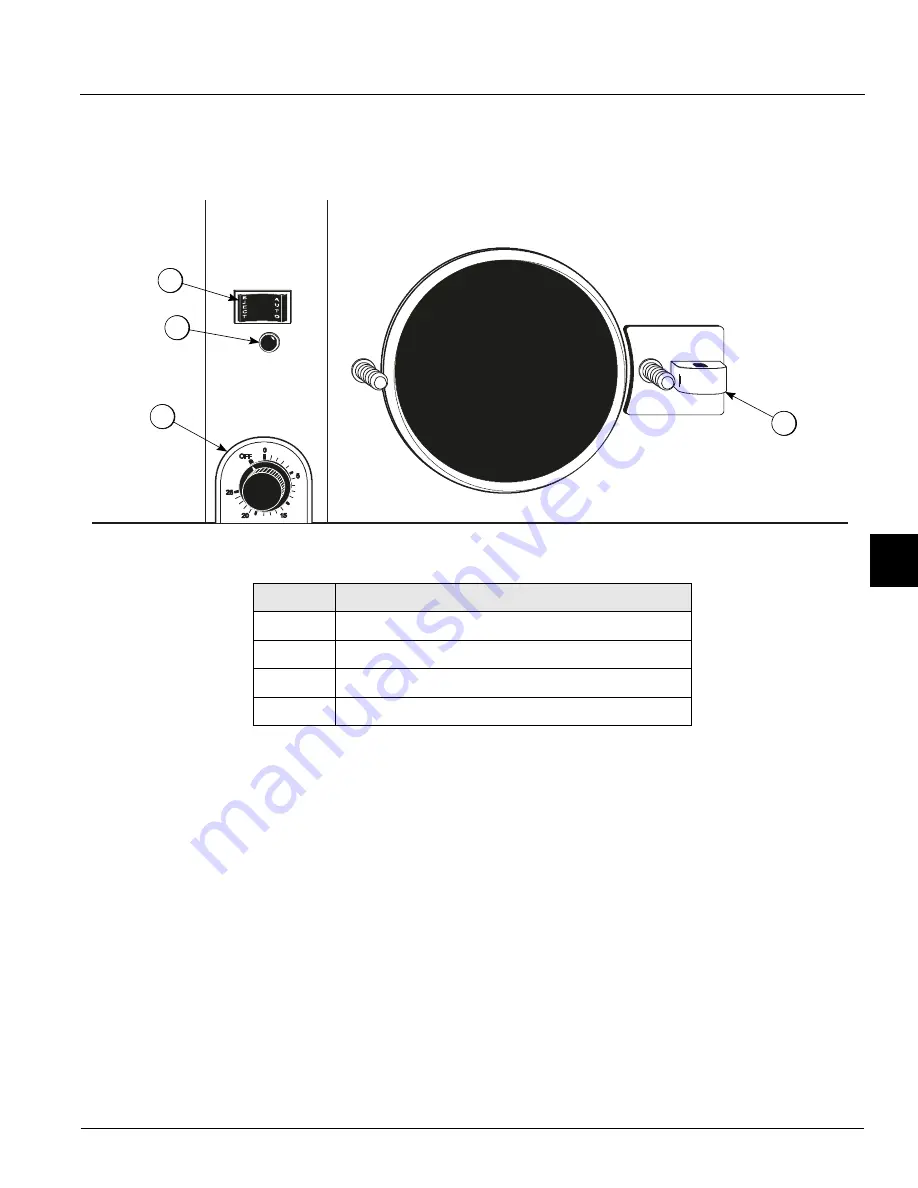

Figure 5-1

Control Switch

When the control switch (1) is placed in the Auto mode

and the timer is adjusted to the desired setting, the

refrigeration system operates. When the switch is placed

in the Eject mode, only the beater motor operates.

Orange Dial Light

Located below the control switch is an orange dial light

(2). When the control switch is in the AUTO position, this

light turns on, indicating the refrigeration system is

operable when the timer is set.

Safety

Never empty the contents of the freezing cylinder while

the control switch is in the AUTO position. Always put the

control switch into the EJECT position when drawing

product from the freezing cylinder. As an additional safety

feature, this machine does

not

operate if the door is

open.

Timer Control

Model 104 uses a timer control (3) to operate the

compressor and determine the viscosity of the product.

After the desired amount of product has been added to

the freezing cylinder, turn the timer for the amount of

refrigeration required for the batch. The timer setting

varies due to mix variations and desired finished product

viscosity.

Item

Description

1

Control Switch

2

Orange Dial Light

3

Timer Control

4

Door Hinge

1

2

3

4

Содержание 104

Страница 8: ...1 4 TO THE INSTALLER Model 104 To the Installer 1 Notes...

Страница 14: ...3 4 SAFETY Model 104 Safety 3 Notes...

Страница 18: ...4 4 PARTS Model 104 Parts 4 Notes...

Страница 30: ...7 2 OPERATOR CHECKLIST Model 104 Operator Checklist 7 Notes...

Страница 32: ...8 2 TROUBLESHOOTING Model 104 Troubleshooting 8 Notes...

Страница 34: ...9 2 PARTS REPLACEMENT SCHEDULE Model 104 Parts Replacement Schedule 9 Notes...

Страница 40: ...11 4 LIMITED WARRANTY ON PARTS Model 104 Limited Warranty on Parts 11 Notes...