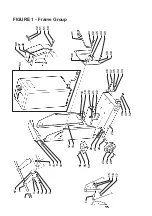

• This saw is equipped with high tensile V-belts.

Belts are properly tensioned at the factory.

• To obtain accurate V-belt setting, a V-belt

tension tester should be used. Apply load at the

center of the belt span. Deflection should be 1/5"

with a 5 to 6 pound load.

After several hours of use it may be necessary to

adjust the tension of the belts (moderately). To do

this proceed as follows :

Release the screws fixing the motor to the

chassis.

Turn the tensioning screw (N) at the front of

themachine one quarter turn; this screw

pushes the motor backwards [

FIG.

6].

At normal tension, counterlock the nut of the

screw (N).

Relock the motor fixing screws.

11

Engine belt tension

Never set belts beyond original

tension

5

English

• Release the lever (by pressing simultaneously on

the button) and pull it towards you to release the

blade from the groove.

• Lock the machine in the high position by means

of the lever (by releasing the button).

• Turn off the water supply.

• Allow the engine to turn at low speed.

• Stop the engine (consult the engine maintenance

manual).

8

Stopping the machine

Emergency stop

(engine) :

Operate the switch on the machine's

control panel.

Motor off.

• Several causes can result in the blade stopping

in the sawing groove or the machine stopping:

Tension of the belts,

Lack of fuel,

Excessively fast feed or descent, etc.

• In all cases remove the blade from the groove

and check the machine thoroughly.

Entrust repairs to authorised dealer

only

9

Incidents during sawing

• After use, clean the machine.

• Lubrication: apply a moderate amount of bearing

lubricant to the nipples in the depth adjustment

chassis (depending on the frequency of use).

10

Maintenance

(with the engine stopped)

"Engine Maintenance" : refer to the

engine maintenance booklet.

OIL

• Check ENGINE OIL daily. Read engine owners

manual for OIL and OIL FILTER change

intervals. Use :

SAE 10W30 motor oil with API class MS, SD,

SE or better for PETROL engines.

API class CD or CE for Hatz diesel.

• To empty the motor, place a funnel at the drain

outlet (V) [

FIG

.

X

5].

Dispose of the old oil as laid down by

the regulations in force.

AIR FILTER

• Read engine owners manual for maintenance

intervals. For extremely dusty conditions you

may have to clean the air filter element 2 to 3

times a day.

• Replace any damaged filters or gaskets.

Store in a safe place out ot reach of

children.

Remove all adjustment tools and

wrenches

Store diamond tool in a safe place so

it cannot be bent or damaged.