Adjustments and Tests

165

7.

If the printer is online, press the

ONLINE

key to place the printer offline.

Press the

MENU/ENTER

key and “OFFLINE / QUICK SETUP.” displays.

8.

On the control panel, press the

U

+

V

keys to unlock the

ENTER

key.

“ENTER SWITCH UNLOCKED” briefly displays. (If “LOCKED” displays,

simply press

U

and

V

again. This is the default key combination. The

lock/unlock key combination can be programmed by the user. If

U

+

V

does not unlock

ENTER

, get the new key combination from the user.)

9.

Press the

Y

key until “DIAGNOSTICS” displays.

10. Press

V

. “DIAGNOSTICS / Printer Tests” displays.

11. Press

V

.

“SHIFT / RECYCLE” displays.

12. Press

Z

until “Paperout Adj.” displays.

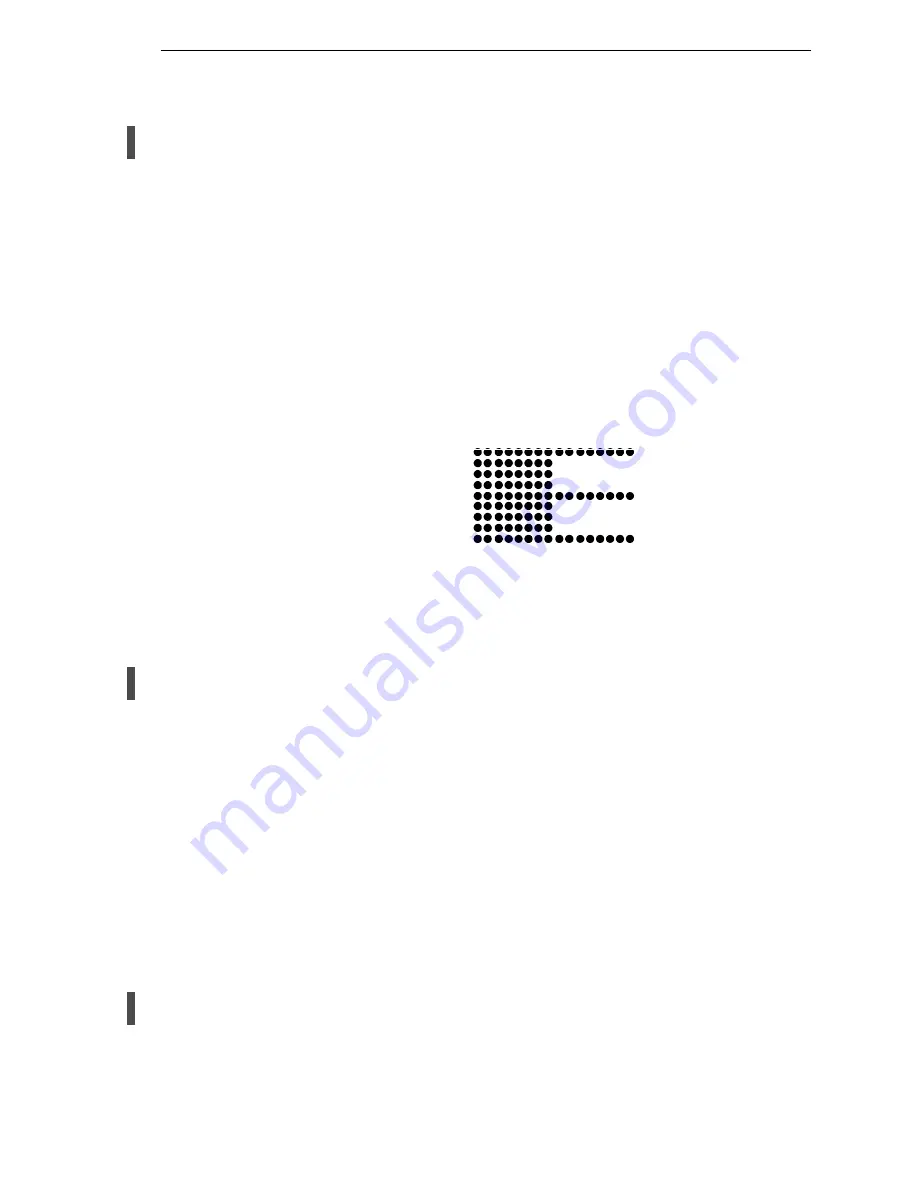

This test will print a vertical “comb” pattern at around column 70, each

long bar separated by three shorter bars. An enlarged example of the

comb pattern is shown below.

13. Press

ENTER

until the Paper Out Adjustment test starts. The comb

pattern will print until the display shows “LOAD PAPER” and the audible

alarm sounds.

14. Open the platen and move the paper up with the vertical position knob

and examine the area of the page perforation.

If the bottom of the comb just meets the perforation, the paper out

adjustment distance is correct, skip to step 27. (1 or 2 dot rows above the

perforation is OK; 5 to 7 dot rows above or any dots below the perforation

mean adjustment of the Paper Out Dots value is required.)

If the comb pattern stopped short of the perforation or printed beyond the

perforation, go to step 15.

15. Measure how short or long the comb pattern printed by counting the

number of dot rows needed to reach the perforation, or the number of dot

rows that printed beyond the perforation.

NOTE:

You can use the long bars to count the dot rows quickly. There are

three dot rows between each long bar, so each long bar increases the

number of dot rows by four. You can also tear off a small piece of the

comb pattern from the beginning of the pattern and use it as a ruler to

help you measure the dot rows required either to reach the

perforation or back up to it.

16. Close the platen.

17. Press

CLEAR

to remove the fault condition. Press the

MENU/ENTER

key

and “OFFLINE / QUICK SETUP” displays.

18. Press the

Y

key until “DIAGNOSTICS” displays.

19. Press

V

. “DIAGNOSTICS / Printer Tests” displays.

Содержание 6600 Series

Страница 1: ...6600 Series Printers Maintenance Manual Approved Final May 19 2011 ...

Страница 2: ......

Страница 3: ...6600 Series Printers Maintenance Manual ...

Страница 10: ......

Страница 34: ...34 Chapter 1 Maintenance Training for TallyGenicom Products ...

Страница 42: ...42 Chapter 2 Cleaning the Card Cage Fan Assembly ...

Страница 246: ...246 Chapter 6 Organization of this Chapter Figure 38 Top Cover Doors and Casters 183949a 1 2 3 4 5 6 7 9 10 11 12 13 ...

Страница 252: ...252 Chapter 6 Organization of this Chapter Figure 41 Pedestal Details 1 18 3 8 4 5 6 10 11 7 2 12 13 14 15 16 17 18 9 ...

Страница 265: ...Illustrations of Printer Components 265 Parts lists continue on the next page ...

Страница 278: ...278 Chapter 6 Organization of this Chapter ...

Страница 300: ...300 Chapter 7 Printer Interface ...

Страница 305: ...305 Cable Routing Pedestal Model 184043a Exhaust Fan Weld Sensor Cable ...

Страница 320: ...320 Appendix A Cable Assembly 2 Pin Jumper 0 1 Ctr P N 154470 901 ...

Страница 321: ...321 Cable Assembly AC In Power Supply AC Kit P N 153502 901 To Power Supply J1 To Circuit Breaker ...

Страница 322: ...322 Appendix A Cable Assembly AC Power Input AC Kit P N 153502 901 To Circuit Breaker Input Power Connector ...

Страница 323: ...323 Cable Assy PS I O P N 176601 901 NOTE This cable is used on 6620 and 6620Q printers ...

Страница 324: ...324 Appendix A Cable Assembly Card Cage Fan P N 152422 901 PIN 1 PIN 1 ...

Страница 325: ...325 Cable Assembly Control Panel P N 152440 901 PIN 1 PIN 1 PIN 8 PIN 8 Gray Brown Gray Brown ...

Страница 326: ...326 Appendix A Cable Assembly Exhaust Fan P N 152424 901 PIN 1 PIN 1 ...

Страница 327: ...327 Cable Assembly Hammer Bank Logic P N 152421 901 To Shuttle To Controller Board ...

Страница 330: ...330 Appendix A Cable Assembly MPU P N 152425 901 PIN 1 PIN 3 PIN 2 PIN 1 ...

Страница 331: ...331 Cable Assembly Ribbon Motor Extension P N 154067 001 ...

Страница 332: ...332 Appendix A Cable Assembly Shuttle Motor Drive P N 152420 001 ...

Страница 333: ...333 Frame Cable Power Stacker P N 173824 001 ...

Страница 334: ...334 Appendix A Logic Cable Power Stacker P N 176029 001 ...

Страница 335: ...335 Power Cable Power Stacker P N 174414 001 P1101 P1101 ...

Страница 336: ...336 Appendix A Rail Cable Power Stacker P N 173823 001 ...

Страница 337: ...337 Elevator I O Cable Power Stacker P N 174759 001 ...

Страница 338: ...338 Appendix A Fan Assembly Hammer Bank P N 152416 901 P107 HBF P107 HBF ...

Страница 339: ...339 Magnetic Pickup MPU Assembly P N 150281 901 ...

Страница 340: ...340 Appendix A Switch Assembly Paper Detector P N 152415 901 ...

Страница 341: ...341 Switch Assembly Platen Interlock P N 152417 901 P107 PLO ...

Страница 342: ...342 Appendix A ...

Страница 402: ...402 Appendix D Illustrated Parts Breakdown ...

Страница 446: ...446 Appendix E Illustrated Parts Lists Figure 124 ZTP Hammer Bank Fan and Motors 184049a 9 8 7 3 1 2 11 12 13 14 15 ...

Страница 448: ...448 Appendix E Illustrated Parts Lists ...

Страница 460: ...460 Appendix F Summary ...

Страница 472: ...472 ...

Страница 473: ......

Страница 474: ... 255559 001 255559 001A Approved Final May 19 2011 ...