15

■

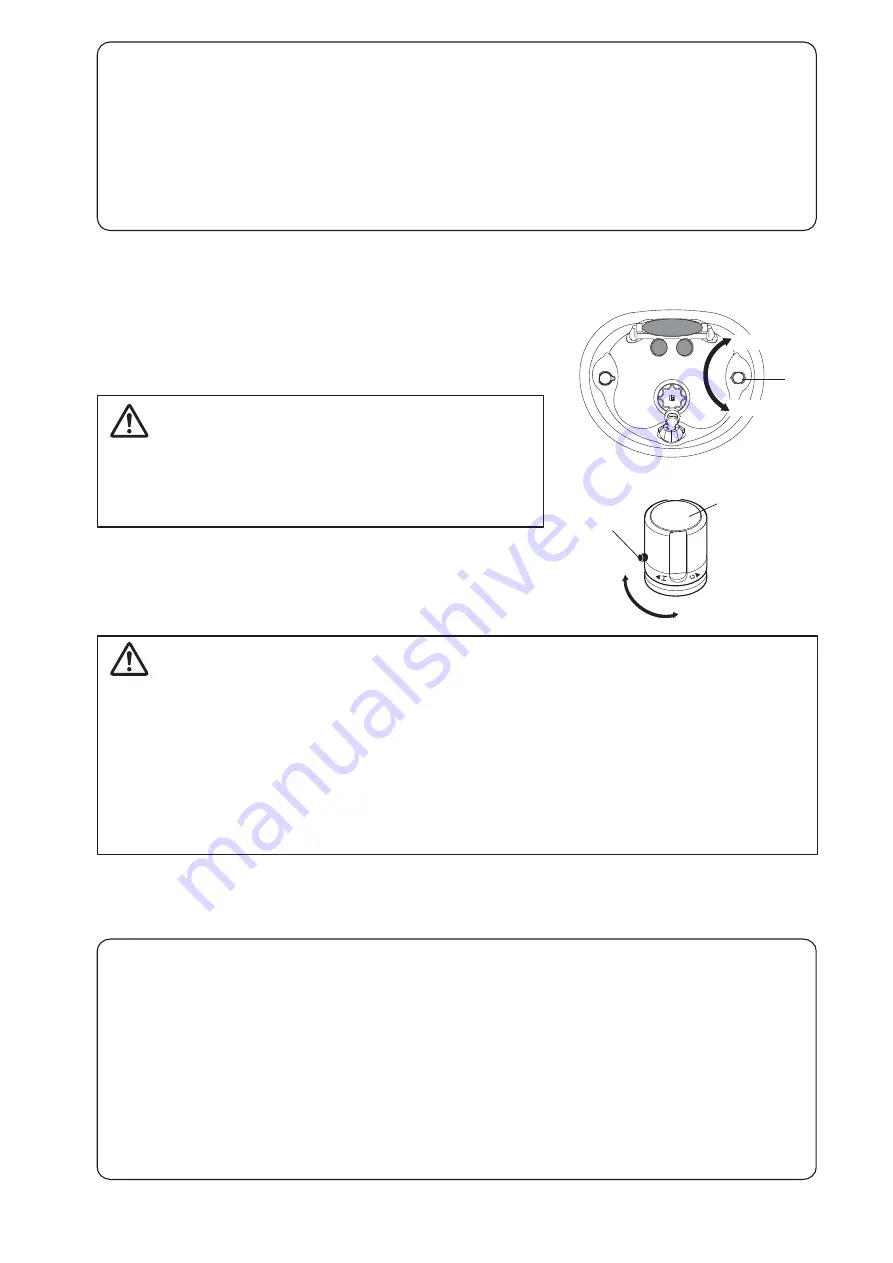

Adjusting the water temperature

*For safety reasons, this product is designed so that hot water of approximately 53°C or higher is not output.

(Conditions: In the case that the supply pressure of water and hot water are the same, normal water temperature is 20°C

and hot water temperature is 60°C.)

1

Turn the thermostatic control knob in the H or C direction to set the

temperature to an appropriate level.

When turning to the H direction, water becomes warm, and when

turning to the C direction, water becomes cold.

2

To use hot water at high temperature (40°C and higher), turn the

thermostatic control knob in the H direction while holding down the

stop button.

・

When adjusting the water temperature, reduce the volume of water,

point the shower head away from the client and check the

temperature by hand. Take care when doing so, as hot water may

come out of the shower head.

・

Return the thermostatic control knob to an appropriate position after use. Continuing to use the hot water with the

knob in the hot temperature position may cause burns.

・

Using other equipment that shares the same water/hot water supply source at the same time may cause unstable

water temperature. Do not execute any quick operation while adjusting the temperature.

・

Operate the thermostatic control knob only after removing metallic objects such as rings and wrist watches, etc.

Failure to follow this instruction may result in contact between the metal and cap of thermostatic control knob resulting

in scratches or cracks on the plated surface and thereby causing peeling of the plating.

・

Before using the product, check that there are no scratches, cracks, or peeling of the plated surface of the thermostatic

control knob. If the plating is peeled off, immediately stop using the product and contact the nearest dealer or Takara

Belmont directly as it may result in personal injury. Continued operation may result in personal injury.

Caution

Caution

・

Depends on the operating environment or conditions, the water discharge amount may change significantly when

controlling the hot water temperature. This phenomena occurs when the hot water temperature exceeds the

recommended values (60°C to 80°C), there is significant difference in the water supply or hot-water supply

pressure, or multiple devices are used at the same time – it is not a product failure.

・

The temperature of discharged water and the preset temperature may differ depending on the operating

environment or conditions.

(The product is designed so that the temperature of the discharged water will be about 40°C when the thermostatic

control knob is turned toward the H position and locked in that position.)

This phenomena occurs when the hot water temperature exceeds the recommended values (60°C to 80°C), there is

significant difference in the water supply or hot-water supply pressure, or multiple devices are used at the same

time - it is not product failure. The temperature of discharged water may be set at approximately 40°C when the

temperature of hot water or the pressure of the water/hot water supply is adjusted and the locking position of the

thermostatic control knob is adjusted.

Note

Note

Depends on the environment or condition that it is used in, the product may have the following conditions. If adjust-

ment or replacement is required, contact the nearest dealer or Takara Belmont directly.

・

A gushing sound may be emitted from the basin unit. (Adjustment is required.) This sound is due to water flowing

fast through pipes as a result of high water pressure or water volume control, and is not indicative of a defective

product. This gushing sound may be reduced by adjusting the water pressure.

・

The tap may become stiffer. (Replacement is required.)

This is due to deterioration of gasket of movable parts or a lack of grease as a result of aging. Replacement of the

gasket or other parts, or a recoating of grease is required. (available at additional cost)

Stop Button

Hot

Thermostatic

Control Knob

Cold

Thermostatic

Control Knob

(H) Hot

(C) Cold