iWorx® HPU3

505-035, Effective: June 30, 2015

13

© 2015 Taco Electronic Solutions, Inc.

• Humidity: 0 to 90%, non-condensing

Agency Listings

• UL Listed for US and Canada, Energy Management Equipment PAZX and PAZX7.

Agency Compliances

• FCC Part 15 Class A

APPLICATION DESCRIPTION

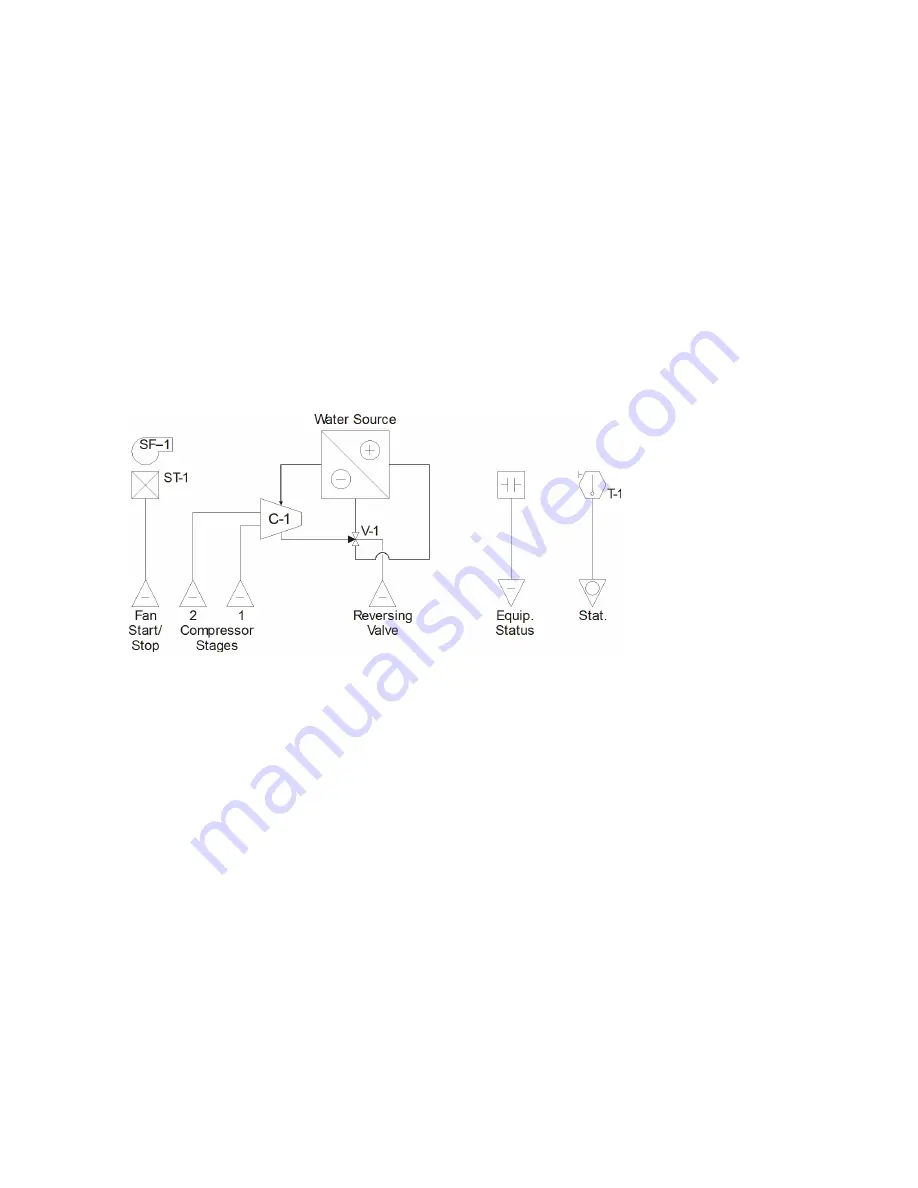

The controller maintains the temperature of a space to a defined setpoint. The figure below illustrates a typical control-

ler application. The control is achieved by sequencing the reversing valve and compressor stages of a liquid source

heat pump based on the current space requirements.

Figure 4: HPU3 Application

The controller controls the starting and stopping of the supply air fan. If the unit enable input indicates plant synchroni-

zation, the fan is energized when there is call for heating or cooling. During the occupied periods, the fan can be config-

ured to run continuously. The fan can be overridden from the local thermostat. If overridden, the fan will run

continuously.

When the temperature increases above the cooling setpoint, the reversing valve cycles to the cooling position. The

compressor stages are sequenced on with a time proportioned control algorithm to minimize excessive cycling. As the

temperature decreases below the cooling setpoint, the compressor stages are sequenced off. When the unoccupied

mode is entered, the cooling setpoint is set up to a separate cooling setpoint for unoccupied mode.

When the temperature decreases below the heating setpoint, the reversing valve cycles to the heating position. The

compressor stages are sequenced on with a time proportioned control algorithm to minimize excessive cycling. As the

temperature increases above the heating setpoint, the compressor stages are sequenced off. When the unoccupied

mode is entered, the heating setpoint is set back to a separate heating setpoint for unoccupied mode.

Each controller interfaces to a local thermostat. The thermostat includes a space temperature sensor, space humidity

sensor, temperature setpoint adjustment, occupancy override, and a fan auto/on selection (depending on the model).

The controller operates in one of two states: occupied or unoccupied. The LCI determines the active operating mode.

The controller maintains the comfort level to a user-defined setpoint during the occupied period, and uses setup and

setback values during the unoccupied period to maintain the space temperature. An optional backup schedule is pro-

vided for cases when the LCI is not available.