iWorx® HPU3

505-035, Effective: June 30, 2015

31

© 2015 Taco Electronic Solutions, Inc.

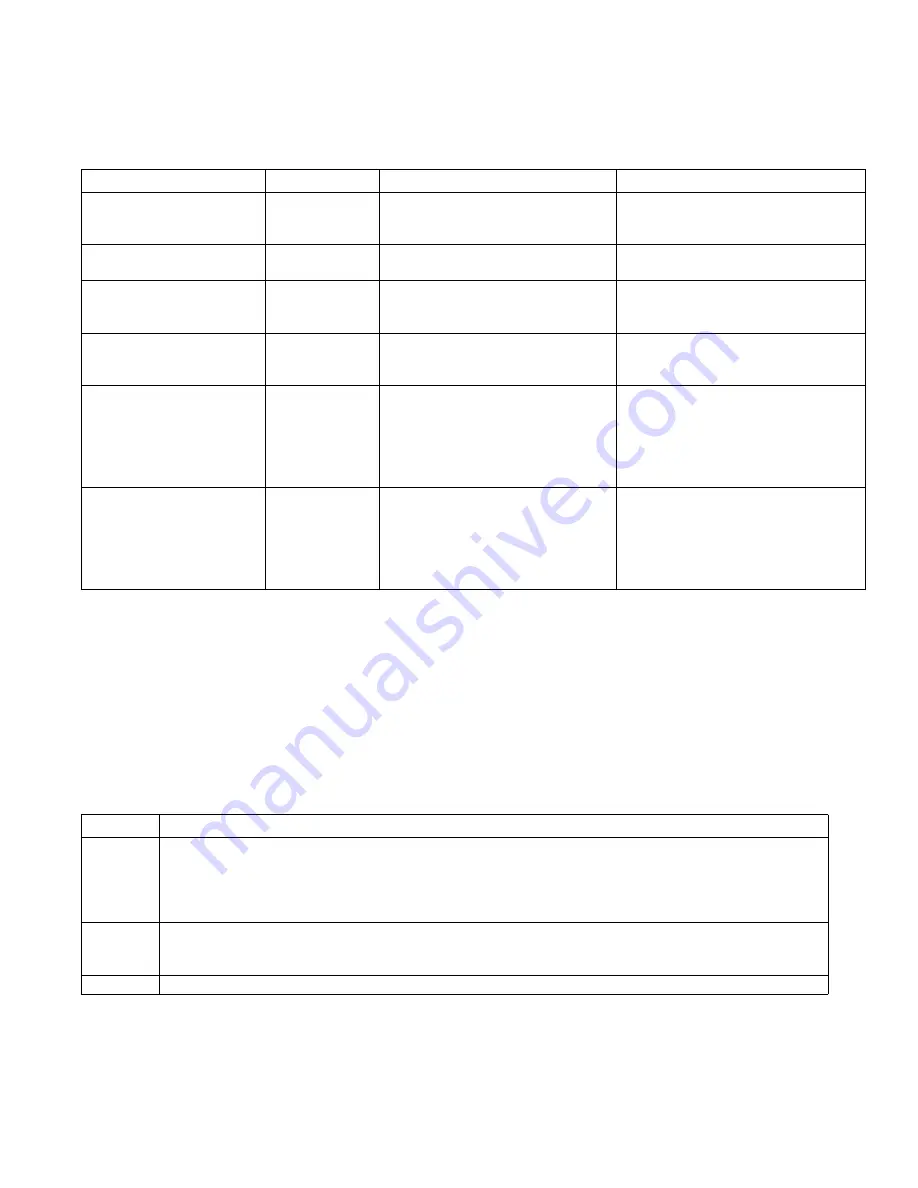

Alarms

The table below describes the alarms that the user may encounter and how to reset them.

TROUBLESHOOTING

Diagnostic LEDs

The controller has 3 LED indicators. These indicators can aid in troubleshooting equipment operation problems. The

following table lists the functions of the controller’s LEDs in the order they appear from left to right on the unit.

Alarm

Range

Alarm Trigger

Alarm Reset

Equipment Failure

Normal, Alarm

Occurs when the controller detects

that the equipment status input contact

has faulted.

The cause of the emergency condition

must be resolved.

Thermostat Failure

Normal, Alarm

Occurs when the thermostat is unable

to communicate to the controller

Automatic when thermostat connected to

the controller.

Space Temp

Normal, Alarm

Occurs when the space temperature

exceeds the specified high limit or

drops below the specified low limit.

Automatic when space temperature

returns within its normal range.

Maintenance

Normal, Alarm

Occurs when the fan, heating, or cool-

ing operating hours have exceeded

their Runtime limit.

To clear the alarm, a user must enter a

new value for the alarm limit or reset the

accumulated runtimes to zero.

High Pressure

Normal,

Soft Alarm,

Hard Alarm

Occurs when the High Pressure Alarm

input is faulted. Alarm is 'Hard' if more

than one alarm happens within 120

minutes. 'Soft' if no previous High

Pressure alarms in the last 120 min-

utes.

Soft Alarm is cleared as soon as Low

Pressure Input is no longer faulted. Hard

Alarm requires Controller Reset.

Low Pressure

Normal,

Soft Alarm,

Hard Alarm

Occurs when the Low Pressure Alarm

input is faulted. Alarm is 'Hard' if more

than one alarm happens within 120

minutes. 'Soft' if no previous High

Pressure alarms in the last 120 min-

utes.

Soft Alarm is cleared as soon as Low

Pressure Input is no longer faulted. Hard

Alarm requires Controller Reset.

LED Indication

Status

– Solid green when running and configured by an LCI (networking)

– Flashing green when running and NOT configured by an LCI (stand-alone)

– Solid red when a fault condition exists (control shut down)

– Blinking Red - the controller has a device failure

– Solid Amber - The controller has not received a LCI ping message in over 10 minutes and is part of a network.

Network

– Yellow while the controller is transmitting data onto the FTT-10A network

– Green when there is network activity

– Off when there is no network activity

Service

– Illuminated when the service pin is depressed or when a controller gets configured by the LCI.