62/64 |

F-B90

Damper Inspection

CAUTION:

Never perform inspection when there is air flowing in the duct connected to the damper.

Do not change the dampers or their structure without the approval of the manufacturer.

The actuator keeps the dampers on stand-by during their life cycle. The operator obeys the applicable regulations and

standards to do regular checks of the dampers. The recommended minimum interval for the inspection checks is 12

months. The manufacturer and/or government authorities must approve the inspecting person and/or process for this

inspection. Operating Journal must be kept during the lifecycle of the damper. The damper's Operating Journal includes

a copy of the approval/s of the inspecting person. If the inspecting person finds differences, the operator must write

these differences in the Operating Journal. Then, he must recommend action to remove these differences.

After you install and start the damper, immediately do initial damper inspection. This inspection obeys the same

conditions as the tvelwe-month inspections.

Do a check of these elements of the external side of the damper:

• The damper housing.

• The blade movement.

NOTE:

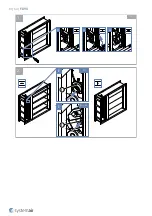

To do a visual check of the internal parts of the damper, dismount the inspection lid or the grille. This will give you

access to the internal parts. Also, if the damper has an mechanism lid, you can open the lid to access the internal parts.

Do a check of these items of the internal side of the damper:

• Make sure that there are no foreign objects or layers of contamination in the air distribution systems of the damper.

• The internal casing of the damper

• The sealings

• The foaming material

• The condition of the damper blade

• How accurately the damper blade closes when it is against the backstop in the closed position.

Recommended Procedure for the Inspection Log (refer to EN 15650)

1. Find the identification of the damper.

2. Write the date of the inspection.

3. Examine the actuator wiring for damage.

4. Examine the wiring of the end switches for damage.

5. Make sure that the damper is clean. If necessary, clean the damper.

6. Do a check of the inspection lid and of the tightness of the cover.

7. Do a check of the blade and of the sealings. If necessary, correct the defects and record the results (where

applicable).

8. Do a functional test of the damper (open and close) (refer to the “Functionality Check” chapter).

9. Confirm the operation of the damper with the control system:

a. Monitor the physical performance of the damper

b. Monitor the signals of the end positions.

c. If necessary, correct and record the defect (where applicable).

10. The damper is part of the HVAC System (Heating Ventilation and Air-conditioning System). Thus, you must do a

check of the full system (refer to the Operational and Maintenance Requirements).

11. Set the system to the operating position (refer to the “Operation Manual”).

12. Record the result in the “Operating Journal” with the name and the signature of the Inspection Technician.

After the inspection, the inspecting person must write the data that follows in the “Operating Journal”:

• Condition of the damper

• Date of the inspection

• Name, Surname and Signature of the employee that did the inspection (make sure that you can read this data).

Содержание 178818

Страница 1: ...F B90 Multiblade Fire Damper Handbook...

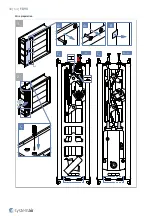

Страница 21: ...21 64 F B90 5 1 1 2 B A1 A2 3 A1 B A2...

Страница 22: ...22 64 F B90 C1 C2 C3 C4 C5 i D 4 1 8 1 Fx D1 D2...

Страница 23: ...23 64 F B90 F3 5 2 E F F3 E1 E2 5 F1 F2 6...

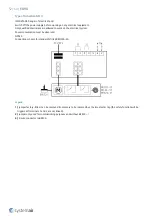

Страница 48: ...48 64 F B90 Wire preparation C1 A1 A2 B C2 C2 H B G A1 A2 B 2 1 C2 C1...

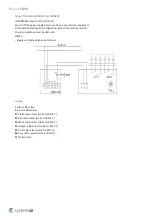

Страница 61: ...61 64 F B90 D1 D2 D3 P13 P13 E E H B G 1 2 H...

Страница 64: ...Systemair DESIGN 2021 08 25 Handbook_F_B90_en GB...