D200-100-00

2

I56-3888-005

USING PIPEIQ™ TO CONTROL OR MONITOR FAAST LT

FAAST LT USB Connection

PC connectivity is provided by an on board USB

B

socket located

in the middle of the FAAST LT unit behind the hinged front cover .

The USB interface allows access to a range of additional options,

via the PipeIQ™ application software (supplied) .

Note: To connect, access or change any FAAST LT configuration

parameters, the device must be in

Maintenance

mode (See

Password Procedure

to enter

Maintenance

mode) .

Connecting a PC to a FAAST LT Device for the First Time

Minimum System Requirements

Microsoft Windows 7, 8 or 10 (for 10, PipeIQ™ version 2.5.1 or

higher required), XP - SP3 (not recommended).

1 GB of RAM .

Graphics hardware with 128 MB of memory and support for

OpenGL 2.0 or later.

5 GB of free hard disc space

The USB driver will be installed automatically during the PipeIQ™

installation procedure . This should

NOT

be declined during the

installation process .

Note: It is strongly recommended that some form of training

is taken before using PipeIQ™ (contact your distributor for

information on this)

. The information provided in this manual is

only a short overview .

Power-On/Initialisation

A FAAST LT device always powers on in the

Initialisation

state where

internal checks are completed before entering the

Normal

state .

Normal

In the

Normal

state the FAAST LT operates as a smoke detector .

The main button actions are not active, apart from the combination

Reset + Disable

which shows the fan speed number, and the

Reset

button itself providing access to the

Password Procedure

to

go to the

Maintenance

state .

Note:

For the loop based FAAST LT device, the module address

will only respond to a panel poll when in

Normal

mode .

Maintenance

When the correct password is entered, a FAAST LT device will

enter the

Maintenance

state (See

Password Procedure

for more

information) . The front panel buttons are enabled for maintenance

functions and the FAAST LT unit can be linked to a PC . (See

Remote Maintenance

state) .

A FAAST LT device will automatically time-out of the

Maintenance

state after a preset period of inactivity (Default is 5 minutes) .

Remote Maintenance

The USB connection can only be used when the FAAST LT

device is in the

Remote Maintenance

mode . To enter the

Remote

Maintenance

mode, first put the device into

Maintenance

mode,

open the hinged front cover and connect to a PC with a USB cable

(within 5 minutes) . In

Remote Maintenance

mode it is possible to

control, monitor and re-programme the FAAST LT device via the PC

using PipeIQ™ (Version 2.3 and above).

The

Remote Maintenance

mode does not have a time-out. The

FAAST LT device will return to

Maintenance

mode when the USB

cable is unplugged and the door is firmly shut. (Note: if the door is

not shut within 5 minutes of removing the USB cable, the unit will

enter

Service

mode .) .

Service Mode

When the FAAST LT device is in

Normal

, the

Service Mode

state is

entered automatically when the front cover is opened . The FAAST

LT unit switches off the power to the unit . Once the service action

is complete, and the front cover is closed, the FAAST LT device

restarts automatically .

Power Out Of Range State

If the PSU voltage is out-of-range, the FAAST LT unit will stop

working, switching off the power to the unit and signalling a power

fault and a general fault .

The FAAST LT device remains in this state until it is re-powered or

restarts automatically when the supply voltage returns to within the

correct range .

PASSWORD PROCEDURE (To enter Maintenance Mode)

Press and hold

RESET

; left hand flow indicator will turn yellow

then green .

Release

RESET

and FAULT indicator will switch on green . The left

hand flow indicator will blink green indicating the device is ready

for the first digit.

Press

DISABLE

to increment the LEDs 1…9; press

TEST

(tick

button) to select a digit .

The flashing airflow segment will turn solid green and the next

segment will begin to flash indicating set the next digit. When the

4th digit is selected, all 4 airflow segments are turned off. If the

password is accepted the FAULT indicator will remain green and

the unit enters

Maintenance

mode . If the password is incorrect

the FAULT indicator flashes yellow and the unit remains in

Normal

mode .

The Default password in 3111

.

If no button is pressed for 10s during the password sequence, the

unit returns to

Normal

mode . If there is no activity in

Maintenance

mode for 5 minutes (default), the fault indicator blinks green for 15s

and then the unit returns to the

Normal

state .

When the USB cable is plugged into the unit, it switches to

Remote

Maintenance

mode; the maintenance time-out is disabled.

AN INTRODUCTION TO PIPEIQ™

Overview

The PipeIQ™ software program is a convenient and powerful

Windows

®

based application that can be used to set-up and

monitor the performance of FAAST LT Aspiration devices via a

graphical user interface on a PC .

PipeIQ™ also provides facilities to develop and verify the

performance of pipe network solutions, configure the design

parameters to suit local fire codes and standards and generate

pipe layout diagrams, BoMs, parameter tables and event log

reports .

With a detailed Help Menu to guide the user through the different

screens and options, PipeIQ™ is a comprehensive package to

support the use of the FAAST LT detector in aspirating applications .

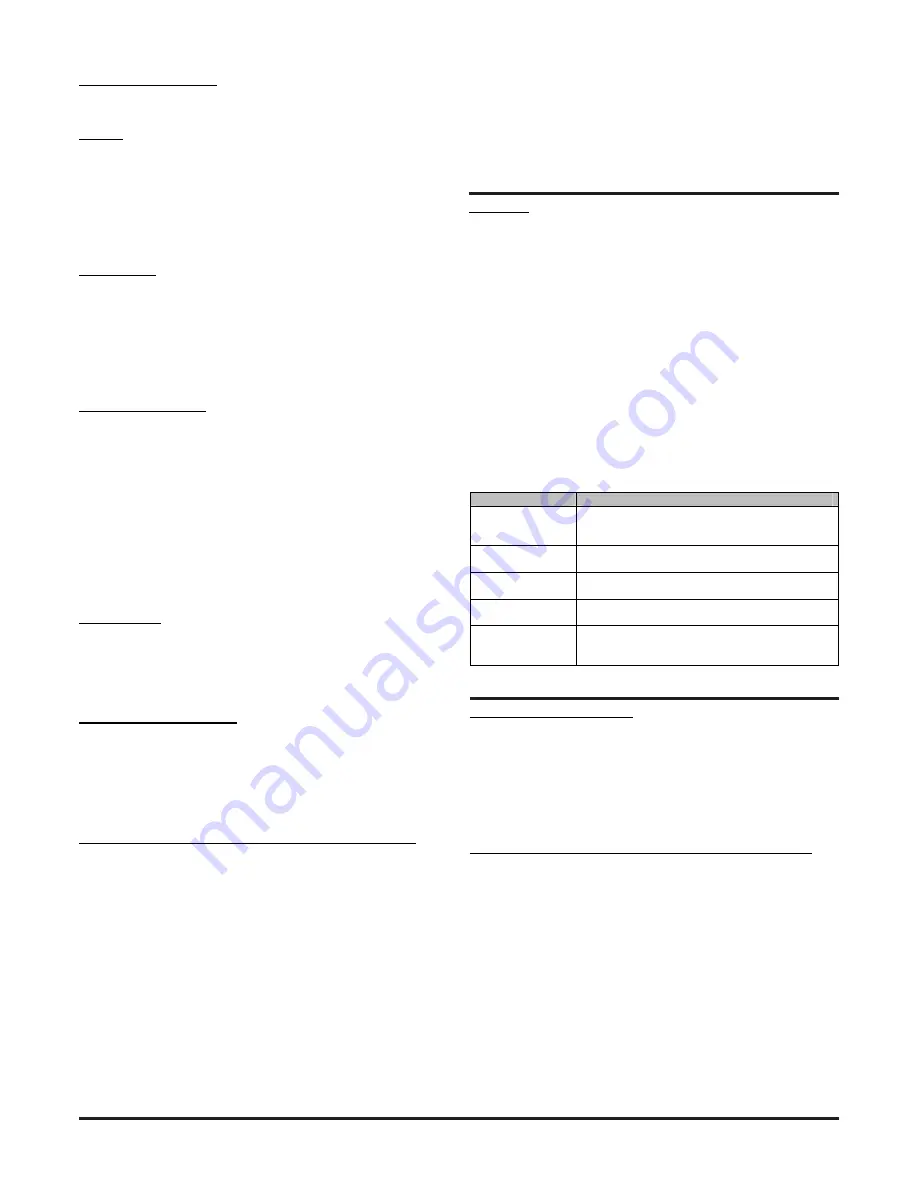

The PipeIQ™ User Interface

The graphical user interface for PipeIQ™ includes a title bar, menu

bar, toolbar, left pane, right pane, and status bar as described in

the following table:

Option

Action

Menu bar

Contains six menus that perform various

tasks such as new, open, close, save,

change the view, etc

Toolbar

Contains buttons to create, open or save

projects

Left pane

Displays all the project elements in a tree

structure

Right pane

Displays detailed information of the item

selected in the left pane

Status Bar

Displays the type of operation (on tabs at the

bottom of the Left Pane)

Tabs: Configuration; Pipe Design; Monitoring