14

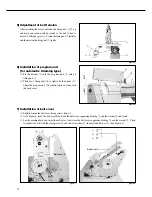

For 470 motor (external synchronizer)

Turn the pulley manually to position the needle bar at the lowest point about to move back up. Then, loosen the fixed

screws on the film as in Figure 10 on page 13 and align the

“

DOWN

”

film with the film adjustment baseline and the

sensor housing baseline as in Figures 14 and 15. Tighten the fixed screws just enough so that the film does not rotate.

In the same way, place the thread take-up lever at the highest point, then loosen the fixed screws again and adjust the

“

UP

”

film as in shown the figure. Be careful that the

“

DOWN

”

film A that was tightened before does not move

when adjusting the

“

UP

”

film.

Figure 15 is an enlarged view of the film location. As in the figure, match the sensor to the end of the arrow.

Sensor

Base

DOWN

Film

Adjusting

Base

Setting the film when

the needle is in a up-

stop position

Setting the film when the

thread take-up lever is at

the highest point

Sensor

Baseline

Setting

Area

Film-Adjusting

Arrow

[Figure 14]

[Figure 15]

9) Description of back tack button

(for automatic trimming type)

Fix the back tack button or reverse button

①

located beside

the switch box of the table with wooden nail

②

. When the

machine is in a

“

stop

”

mode, you can change the up-down

position of the needle bar by pressing the button. Lightly

pressing the button once when the needle is in a down-stop

position will stop the needle bar in a high position. Pressing

the reverse button twice within less than a second when it is

in an up-stop position will stop the needle bar in a low

position.

10) Check for machine stop position

(for automatic trimming type)

Check for the machine stop position after moving the needle

up and down by pushing the reverse button

①

. See whether

the line where belt cover A and B meet and the white carved

sign on the bushing are aligned when the needle is in an up

position. If not, adjustment to the photo film of the

synchronizer or to the location of the magnetic holder will

be necessary since there may be problems with the

trimming. In other words, the needle

’

s up-stop position

should be identical with the stop position of the needle bar

after the trimming operation. (See Figure 16)

[Figure 16]

White

carved sign

Needle

up

Needle

Down

Содержание KM-957 Series

Страница 31: ...31 5 Table Drawing 1 KM 967 ...

Страница 32: ...32 2 KM 967 7 ...