37

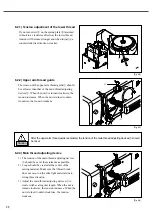

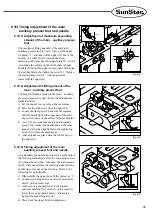

8.6) Needle and Hook Timing

Set the stitch length at minimum and place the needle

①

at 2mm above the lowest position. Then the hook edge

②

is positioned at the needle center. The appropriate

distance between the needle groove and the hook edge

②

is 0.1mm. At this time, the hook edge

②

should not

contact the needle

①

. If the above conditions are not

met, perform the following adjustments.

8.6.1) Adjustment of Needle and Hook Timing

1) Open the hook cover.

2) Lean the machine backward. Loosen the lower

shaft collar fixing screw

①

and set the needle

position 2mm above the lowest position.

3) Turn the hook shaft to place the hook edge at the

center of the needle and tightly fasten the fixing

screw

①

for the lower shaft collar.

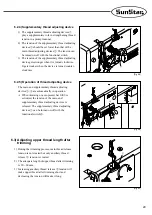

8.6.2) Clearance adjustment between needle

and hook

1) Loosen the needle plate base fixing screw

③

and

then the hook base fixing screws

④

,

⑤

. Adjust the

hook base in the arrow direction and set the

distance between the needle

①

and the hook edge

②

to be 0.1mm.

2) Tightly fasten the hook base fixing screws

④

,

⑤

after adjustment is complete.

3) Adjust the hook base to set the hook shaft center

of the hook base in line with the hook shaft center

of the hook base.

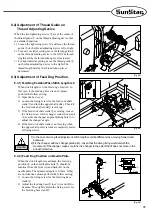

2mm

③

⑤

④

①

②

0.1mm

0.1mm

①

[Fig. 8-9]

[Fig. 8-10]

[Fig. 8-11]

2mm

0.1mm

②

①

1) When adjusting the distance between the needle and the hook, make sure that the needle guide

and the needle do not contact each other.

2) When replacing a needle, check the distance between the needle and the hook.

Caution

Содержание KM-1080 Series

Страница 2: ......

Страница 13: ...13 4 4 2 Flat table Fig 4 4 ...