Page 17

www.sunrotor.com

MPPT

(

Flashing Green

): The MPPT (Maximum Power Point Tracking) monitors the power input from

the solar panels and adjusts the voltage and current to gain the highest performance of the pump.

This indicator light will flash green when the MPPT is working properly.

ERR_1

(

Solid Red

): This light will usually illuminate when there is an overcurrent issue. If the pump

is drawing too high of an amperage, the overcurrent protection will engage to protect the pump,

motor, and controller. The pump will be shut down until the system is reset. It should automatically

start after 20 minutes. If not, cycle the power switch and verify the

ERR-

1 light has turned off. If it

repeats, call Technical Support. Overcurrent can be caused by pump or motor problems, shorts in the

wiring, or even a blockage in the piping. Please consult your Authorized SunRotor

®

Dealer for

technical support, or contact SunRotor

®

Technical Services Team directly at 1(866) 246-7652.

LOW POWER

(

Solid Orange

): This indicator light will illuminate when there is not enough power to

operate the pump or when the pump motor cannot start because of blockage, torn stator, or other

factors. Low sunlight or hazy conditions are usually the cause.

Tank_F

(

Solid Red

): This light indicates the storage tank is full. When water in the tank reaches its

desired level, the float switch rises and closes the circuit. The pump will shut down until the water

level decreases and the remote switch returns back to the open position.

Well_L

(

Solid or flashing Red

): This indicator light is illuminated when the water level in the water

source has dropped below the sensor. When the low water sensor is tripped, the pump is shut down,

and the timer will start as long if it has been set above zero (red light flashes when timing). The

pump will restart when this time expires. The time is adjustable between 0 and 30 minutes.

6.4

R

EMOTE

F

LOAT

S

WITCH

The purpose of a float switch is to turn the pump off when the storage tank fills, and to turn it back

on after the level drops again. The use of a float switch is highly recommended to reduce the running

time and to prevent waste of ground water. It can control the pump from a long distance away as

long as the proper wire is used. Ask your Authorized SunRotor

®

Dealer about pricing and

applications for float switches.

7

P

UMP

P

REPARATION

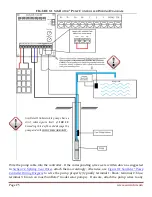

7.1

W

IRE

S

IZING

All SunRotor

®

solar pump systems require a minimum of 10 gauge pump cable, except when the

TDH is greater than 300 ft., in which 8 gauge pump cable is required. It is also recommended that

any and all additional instrument cable not provided with purchased sensors and float switches be a

minimum of 18 gauge shield twisted-pair cable. This will help prevent damage from ambient or

transient lightning strikes. If unsure of the proper wire sizing, contact your Authorized SunRotor

®

Dealer or the SunRotor

®

Technical Services Team at 1(866) 246-7652.

Содержание Solar Pump

Страница 1: ...SunRotor Solar Pump Installation and Resource Manual...

Страница 36: ......