4-10

StorEdge L280 Service Manual • February 1998

4.8

Running an Internal Test

1. To run an internal test, press the Next key to enter the following:

2. When

TEST *

is displayed, press

Enter

.

3. Press the

Next

button until the desired test is displayed, and press

Enter

.

4.

NUM LOOPS 1

is displayed, where the 1 is flashing. Press

Next

until the number of

the desired test loop is displayed, then press

Enter

.

Note –

Press

Cancel

at any time to abort a test. The last test cycle will complete

before cancelling.

TEST CANCEL

-

WAIT

is displayed while the last test cycle

completes.

Descriptions of the internal tests available from the control panel are in

TABLE 4-4

.

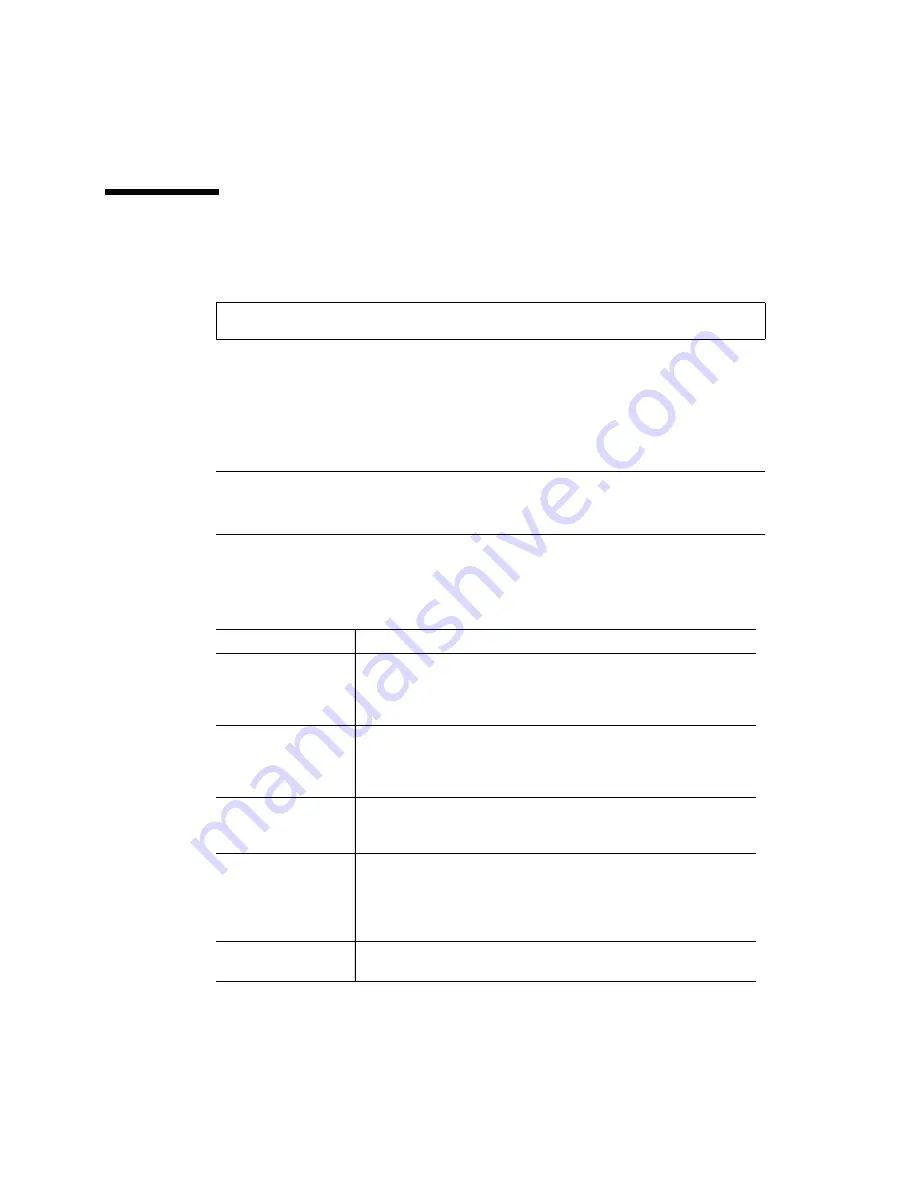

ADMIN * / PSWD ### ### ### / TEST *

TABLE 4-4

Tests Available From the Control Panel

Test Name

Description

EMPTY DRIVE

Do not run this test if the Autoloader contains a tape cartridge with

data. Moves a cartridge out of the drive mechanism and returns it

to its home storage slot if the locations are known, otherwise a

cartridge is placed into the first available storage slot.

REWIND MEDIA

Do not run this test if the Autoloader contains a tape cartridge with

data. Rewinds the tape in the drive and opens the solenoid in the

drive handle. Go to

OPEN DRV HANDLE

to open the drive and

remove the tape.

LOAD/UNLOAD

Selects a random full slot and moves the tape to the drive. After

the tape loads, the transport moves to another slot and then

returns to the drive, unloading the tape to its home slot.

DRIVE IO

If the drive is empty, moves a tape cartridge from a random full

slot to the drive. If the drive is full, moves a tape cartridge from

the drive to the transport. It then moves the cartridge back to its

original location.

FAIL

is displayed if there are no cartridges in

the autoloader or if all storage slots are full.

SLOT IO

Moves a tape from a random full slot to the transport. The tape is

then moved back to its home slot.

Содержание StorEdge L280

Страница 10: ...x StorEdge L280 Service Manual February 1998 ...

Страница 11: ...xi ...

Страница 12: ...xii StorEdge L280 Service Manual February 1998 ...

Страница 16: ...xvi StorEdge L280 Service Manual February 1998 ...

Страница 20: ...xx StorEdge L280 Service Manual February 1998 TABLE 5 3 Solenoid Mechanism 5 10 ...

Страница 44: ...1 20 StorEdge L280 Service Manual February 1998 ...

Страница 52: ...2 8 StorEdge L280 Service Manual February 1998 ...

Страница 86: ...4 22 StorEdge L280 Service Manual February 1998 ...

Страница 98: ...5 12 StorEdge L280 Service Manual February 1998 ...