3

2. Storage

2-1) Temporary storage

(1) Store PARAMAX DRIVE FOR AIR COOLED CONDENSERS in a clean, dry, covered storage area.

2-2) Long-term storage

(1) The oil seal will deteriorate when exposed to high temperatures and UV rays. Inspect and replace the oil seal after

long-term storage if there are any signs of damage or cracking.

(2)

(3)

. Do not store PARAMAX DRIVE FOR AIR COOLED CONDENSERS outdoors or in a wet location.

3. Transport

4. Installation

CAUTION

DANGER

Never stand directly under a unit suspended by a crane or other lifting mechanism ; otherwise personal injury

or death may result.

CAUTION

Every 2 - 3 months after shipment, operate PARAMAX DRIVE FOR AIR COOLED CONDENSERS with the

recommended lubricant for 5 - 10 minutes. If this is not possible, or when PARAMAX DRIVE FOR AIR COOLED

CONDENSERS is to be stored for more than 6 months, fill the unit with the proper amount of vapor phase inhibitor

(JIS NP20 or its equivalent) according to the inhibitor manufacturers recommendations.

After starting PARAMAX DRIVE FOR AIR COOLED CONDENSERS, check that it is free from abnormal sound,

vibration, or heatbuild-up. (If any kind of anomaly is observed) contact the nearest agent, dealer, or service office

immediately.

When storing PARAMAX DRIVE FOR AIR COOLED CONDENSERS for any extended periods of time before use,

consider the following important points.

Otherwise, personal injury or damage to the equipment and/or lifting device may result.

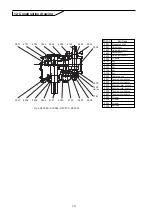

Before hoisting, check the weight with the rating plate, crate, performance specifications, catalog, etc. Never hoist

a PARAMAX DRIVE FOR AIR COOLED CONDENSERS that exceeds the rating of the crane or other mechanism

being used to lift it ; otherwise, injury or damage to the unit and/or lifting device may occur.

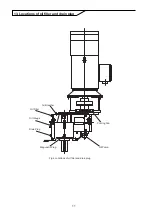

Do not place any objects that will hinder ventilation around PARAMAX DRIVE FOR AIR COOLED CONDENSERS;

otherwise, cooling effect is reduced, and may lead to a possible fire hazard due to excessive heat build-up.

Do not step on or hang from PARAMAX DRIVE FOR AIR COOLED CONDENSERS; otherwise, injury or

damage to the machine may result.

Do not touch the key way at the shaft end or on the inside of PARAMAX DRIVE FOR AIR COOLED

CONDENSERS; otherwise, injury may result.

Do not use PARAMAX DRIVE FOR AIR COOLED CONDENSERS for purposes other than those shown on the

rating plate or in the manufacturing specifications; otherwise, electric shock, personal injury or damage to the

equipment may result.

Do not place flammable objects around PARAMAX DRIVE FOR AIR COOLED CONDENSERS; otherwise, fire may

result.

Do not step on or hang from PARAMAX DRIVE FOR AIR COOLED CONDENSERS; otherwise, injury or

damage to the machine may result.

Exercise ample care not to drop PARAMAX DRIVE FOR AIR COOLED CONDENSERS during transport. When a

hanging bolt or hole is provided, be sure to use it. After mounting PARAMAX DRIVE FOR AIR COOLED

CONDENSERS on a system, however, do not hoist the entire system using the hanging bolt or hole.

Содержание PARAMAX SFC Series

Страница 14: ...GM2202E 1 0 2004 2...