27

INSTAllATIoN AND oPERATIoN

WARNING!

Never add gasoline to diesel fuel tank - serious damage to the engine will result.

5.

If necessary, add lubricating oil to the compressor sump. Refer to

5.3 Compressor Lubrication on page

for lubricating oil specifications.

6.

Check battery posts and cable clamps to assure proper contact. Connect positive cable and negative

cable battery terminals.

4.5

NORMAL STARTING

1.

Inspect the compressor, engine and other assemblies for damage or loose connections.

2.

Check engine coolant, oil, fuel, and battery fluid levels. Check compressor receiver oil level.

3.

Close service valves.

4.

Set start-run valve to

START

position.

5.

Turn engine start switch to allow unit to rotate a few revolutions so that the unit will turn freely.

6.

Turn ignition switch to

ON

position. Allow display to boot up and show gauges.

7.

Turn ignition switch to

START

position and hold until engine starts.

8.

let engine warm up to 140°F. Set start-run valve to

RUN

position. Compressor is now ready for full load

operation.

NOTE!

If the engine stops, do not attempt to restart with the oil receiver under pressure.

4.6

NORMAL STOPPING

1.

Position start-run valve to

START

. Close all service valves.

2.

Run engine at low idle for 1 to 2 minutes.

3.

open and close the service valve to reduce pressure to approximately 60 psi or less.

4.

Turn ignition switch to

OFF

.

4.7

EMERGENCY STOP

In case of emergency turn the ignition switch to the

OFF

position.

Содержание D260UJD4PTOW

Страница 4: ......

Страница 6: ...vi About This Manual ...

Страница 14: ...6 Safety ...

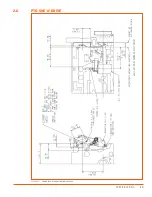

Страница 21: ...13 Specifications 2 6 PTO SAE A DRIVE Figure 2 5 Power Take Off Auxiliary Drive Specs ...

Страница 22: ...14 Specifications ...

Страница 32: ...24 Component Description ...

Страница 44: ...36 Installation and Operation ...

Страница 58: ...50 Troubleshooting ...

Страница 125: ...117 Parts Catalog ...

Страница 134: ...NOTES ...

Страница 135: ...NOTES ...