39

MAINTENANCE

5.2

BOLT TORQUE GUIDELINES

5.2.1 INCH FASTENERS

INCH FASTENERS TORQUE

Size

SAE Grade 5 (ft-lb)

SAE Grade 8 (ft-lb)

Dry

Oiled

Dry

Oiled

1

⁄

4

–20

8

6

12

9

5

⁄

16

–18

17

13

25

18

3

⁄

8

–16

30

23

45

35

7

⁄

16

–14

50

35

70

55

1

⁄

2

–13

75

55

110

80

9

⁄

16

–12

110

80

150

110

5

⁄

8

–11

150

110

220

170

3

⁄

4

–10

260

200

380

280

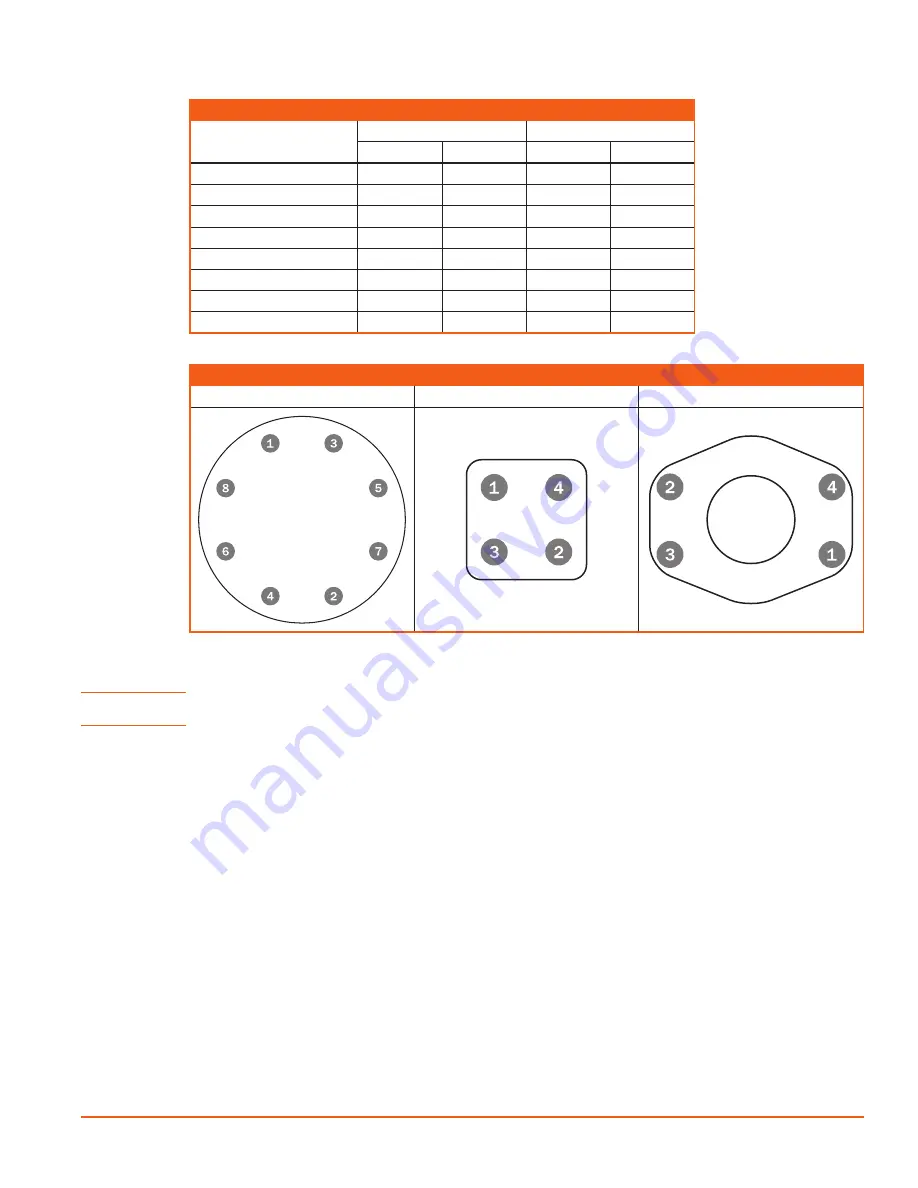

5.2.2 TORQUE SEQUENCE

TYPICAL bOLT TORQUE PATTERNS

Circular Pattern (8-Bolt)

Square Pattern

Flange Pattern

5.3

COMPRESSOR LUBRICATION

Change oil at least once a year, even if the normal oil change period in hours has not yet been reached.

CAUTION!

Never mix synthetic lubricants with hydrocarbon lubricants. Never mix synthetic lubricants

manufactured from different base products. Severe damage to the compressor system may result.

Contamination of non-detergent mineral oils with traces of aTF, or detergent motor oils, may lead to

problems such as foaming and plugging of filters, orifices, and lines. lubricant manufacturers include a

variety of additives in the blending process to enhance lubrication, product life and performance. Mixing

different types or brands of lubricants is not recommended due to the possibility of a dilution of the

additives or a reaction between additives of different types.

Environmental conditions in the area of compressor operation such as the presence of reactive gases or

vapors in the air may lead to chemical changes and premature degradation of the lubricant. The useful life of

synthetic lubricants may extend the normally recommended drain and replace period; however, the user is

encouraged to closely monitor the lubricant condition and to participate in an oil analysis program with the

fluid supplier. When ambient conditions exceed those noted, or if conditions warrant use of “extended life”

lubricants, contact Sullivan-Palatek for a recommendation.

5.3.1 CHECK

The oil level should be checked daily.

1.

Shut down the compressor (or check before the compressor is turned on).

2.

Wait two minutes after the compressor stops to allow the pressure to be relieved and the oil to settle.

3.

observe the oil level in the fluid sight glass. The fluid sight glass should be ½ to ⅔ full.

4.

While the compressor is running, the oil should be visible in the sight glass.

Содержание D260UJD4PTOW

Страница 4: ......

Страница 6: ...vi About This Manual ...

Страница 14: ...6 Safety ...

Страница 21: ...13 Specifications 2 6 PTO SAE A DRIVE Figure 2 5 Power Take Off Auxiliary Drive Specs ...

Страница 22: ...14 Specifications ...

Страница 32: ...24 Component Description ...

Страница 44: ...36 Installation and Operation ...

Страница 58: ...50 Troubleshooting ...

Страница 125: ...117 Parts Catalog ...

Страница 134: ...NOTES ...

Страница 135: ...NOTES ...