21

IV. DISASSEMBLING AND SERVICING

4-1 Troubleshooting

4-1-1 starting difficult

TROUBLE

CAUSE

REMEDY

There is no enough fuel in fuel

tank and fuel cock is closed.

Fill fuel, open fuel cock.

Air vent in the fuel filler cap is

clogged

Dredge air vent.

Improper or clogged main oil

flow hole.

Readjust or clean, blow to get

through.

Needle valve is not closed

properly or start hole is clogged.

Dismantle needle valve and repair,

clean, blow to get through.

Fu

el

suppl

y

is

n

ot

sm

oot

h

or

no

fu

el

suppl

y.

Float is damaged or sticking.

Repair float

Fuel is too filthy or deteriorated

Replace

There is water in fuel.

Replace

Too much fuel in engine

Drain extra fuel, dry up spark plug

electrodes.

N

or

m

al

sp

ar

k

pl

ug

spa

rk

So

m

et

hi

ng

w

rong

w

ith

th

e

fu

el

sy

st

em

.

Fu

el

suppl

y

is

no

rm

al

.

Wrong fuel brand

Select proper fuel brand

corresponding with the requirements.

Too much carbon deposit and

dirt around electrodes.

Clear away.

Electrodes are burn damaged

seriously or insulators damaged.

Replace spark plug.

N

or

m

al

h

igh

–

te

ns

ion

lin

e

sp

ar

k

.

Sp

ar

k

pl

ug

is

in

ba

d

co

nd

iti

ons

Improper electrodes gap.

Adjust to proper value.

High

–

tension line is damaged.

Replace

Ignition coil is damaged.

Replace

Magneto loses magnetism.

Replace

N

or

m

al

c

yli

nde

r c

om

pr

essi

on

N

or

m

al

fu

el

su

pp

ly

sy

st

em

.

H

ig

h-

te

nsi

on

lin

e

no

spa

rk

N

or

m

al

sp

ar

k

pl

ug

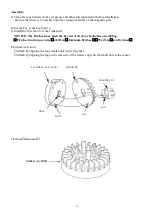

Abnormal gap between the

ignition coil and flywheel.

Adjust gap

TROUBLE

CAUSE

REMEDY

Piston ring is worn to or even

over its wear limit

Replace

Piston ring is broken.

Replace

Piston ring is sticking.

Clear up carbon deposits

Spark plug is not tightened or

without a gasket.

Tighten with a gasket in.

Check cylinder gasket, and the

flatness of the surface by which

cylinder block contacting with

cylinder cover

Air leakage between cylinder

block and cylinder cover

Tighten cylinder cover bolts in

stipulated order to stipulated torque.

A

bn

or

m

al

c

yli

nde

r c

om

pr

es

sion

N

or

m

al

fu

el

su

pp

ly

sy

st

em

N

or

m

al

ign

iti

on

s

ys

te

m

Air leakage in the valves

Check valve. Clearance and tightness,

repair if necessary.

Содержание EA190V

Страница 1: ...EA190V SERVICE MANUAL...

Страница 2: ......

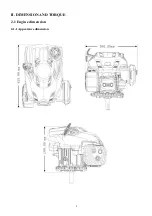

Страница 8: ...8 II DIMENSION AND TORQUE 2 1 Engine dimension 2 1 1 Appearance dimension...

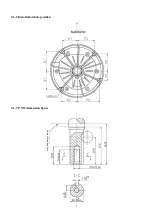

Страница 9: ...9 2 1 2 Installation hole position 2 1 3 P T O dimension figure Engine Mounting Face...

Страница 49: ...49 4 4 Electric diagram Engine switch Engine switch Spark plug Ignition coil Black OFF ON...

Страница 50: ......

Страница 51: ......

Страница 52: ...ISSUE EMD ES7175 September 2015 Revised...