21

© STULZ GmbH – all rights reserved EN/09.2019/G41

cybercool 2 screw original insTrUcTions

Oil transport is carried out by means of differential pressure without a mechanical

oil pump. The compressor contains a fine-mesh suction gas filter, a three-stage oil

separator and an oil heating.

Depending on the compressor type, a part-winding control or star/delta commu-

tation provides for a limitation of peak current. The integrated motor protection

Air outlet grille

Air inlet grille

Compressor

In every unit there are two screw compressors, the cooling capacity of which can be controlled continuously

for each compressor from 25 - 100% by means of an internal capacity control. In combination with the pos-

sibility, to individually operate the refrigerant circuits the total range of capacity control extends from 12,5

- 100%.

The continuous capacity control system shifts the entry point of the refrigerant along the axis of the screw,

which varies the compression section and thus the compression itself. The shorter the compression section,

the lower is the compression and the smaller is the produced cooling capacity.

Condenser

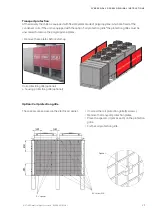

The necessary air for cooling is drawn in across the condenser coils placed on the long side and blown verti-

cally upward through speed-controlled axial fans (EC technology). The W-shaped arrangement of the micro-

channel coils completely made of aluminium increases the heat exchange surface which gets in contact with

intake air and improves the energy efficiency.

device features the following functions:

- Monitoring of motor coil temperature (PTC)

- Monitoring of rotating direction

- Monitoring of oil temperature (PTC)

- Restart interlock in case of malfunction

The compressor cabinet is cooled by air intake grilles in the

base and air outlet grilles to the condenser fan intake area

on both sides. The temperature in the compressor cabinet is

measured by a sensor in the ceiling area.

Evaporator

The tube evaporator is equipped with an anti freeze heater, which is switched in dependance of the chilled

water outlet temperature by the anti freeze thermostat and by the outside air temperature. In the C7000 con-

troller an anti freeze control can be adjusted which in addition to the anti freeze heater also affects the pump

control.

Economizer

The units of the capacity sizes 3302, 4002, 4602, 5102, 6602, 7102, 8002, 9602, 9802, 11102, 12602,

14102 feature an economizer.

The economizer refrigerant line is only opened via a solenoid valve when the compressor is running on 100%.

By this, an arrangement of heat exchanger, solenoid valve and thermostatic expansion valve located between

condenser and electronic expansion valve is designated, by which it is possible to extend the capacity range

upwards.

Downstream the condenser, a plate heat exchanger is installed in which the liquid refrigerant is subcooled, by

letting expand a part of the refrigerant mass flow through a thermostatic expansion valve and by introducing

it in the plate heat exchanger against the main mass flow. The evaporated partial mass flow is drawn in by the

compressor and added at an intermediate pressure level. The additional subcooling upstream the electronic

expansion valve provides a higher exploitation of cooling capacity in the evaporator.

Содержание CyberCool 2

Страница 4: ...4 4 EN 09 2019 G41 STULZ GmbH all rights reserved CYBERCOOL 2 SCREW ORIGINAL INSTRUCTIONS...

Страница 101: ......