Selecting the Proper Stud Collet (Stud Holder)

Listed below are the common collet styles, the choice between these setups is usually a matter of per-

sonal preference

1. The B collet which is a two

-

piece assembly (collet and insert). The insert determines how much of

the stud is engaged in the collet.

2. The CI (Collet Insert) which is a single part and the amount of the stud that is engaged is predeter-

mined.

3. Standard Adjustable Chucks have an adjustable internal screw to manually adjust for the engage-

ment of the stud.

The collet sizes are based on the diameter of the stud to be welded.

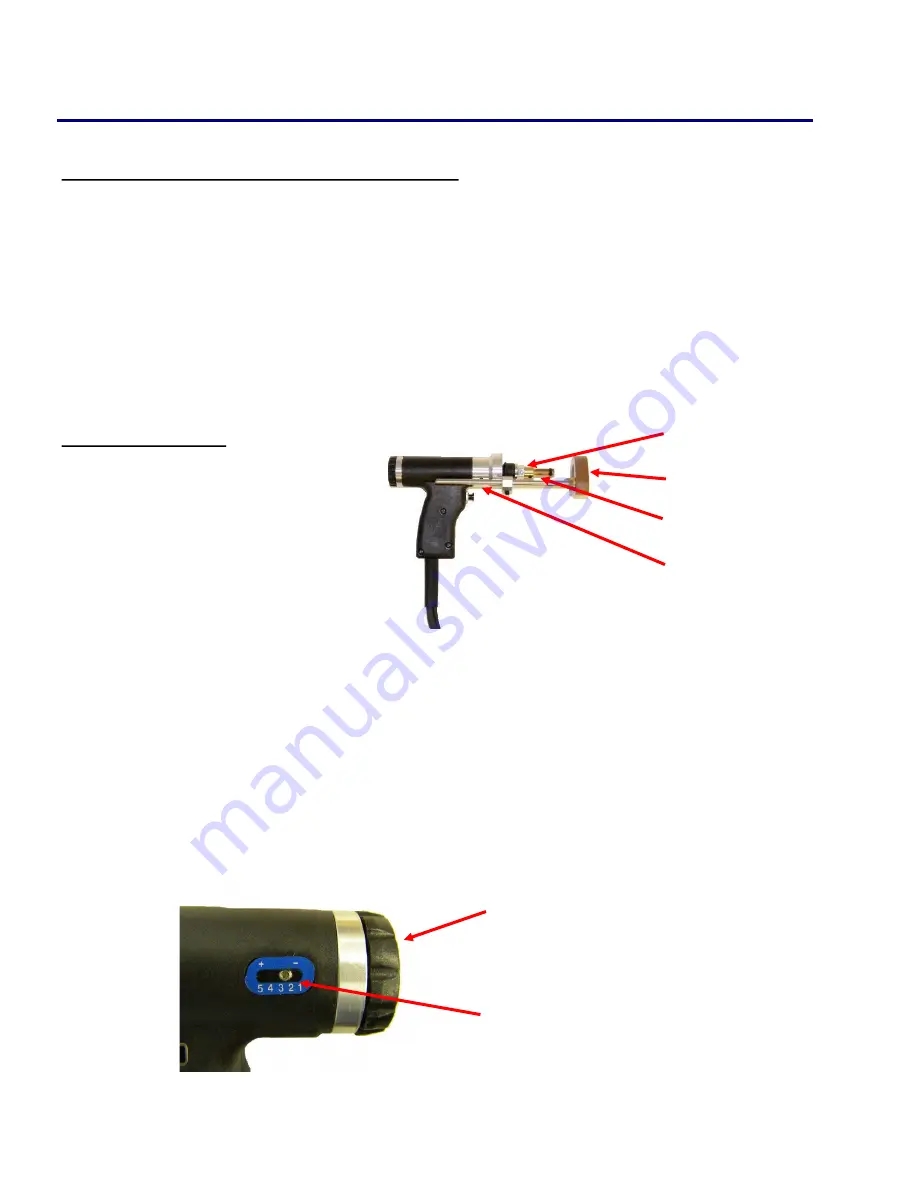

CD Stud Gun Setup

1. Place the collet into the collet

adapter of the stud gun and set the

locking screws to hold the collet in

place.

2. Mount the two legs and foot piece

onto the stud gun. The collet

should be centered through the

opening of the foot piece.

3. Insert the stud to be welded into

the collet.

4. Adjust the leg and foot piece by sliding it into position until approximately 1/8” of the stud pro-

trudes from beyond the foot piece. Lock legs in place with the set screws.

5. The tension setting is adjusted by turning the adjustment cap on the back of the stud gun. On the

side of the stud gun is the tension setting indicator, this displays the tension setting of the internal

spring.

6. The spring tension setting of the stud gun will vary depending on the application. Generally, mild

steel and stainless steel should be set in the 1 to 2 range. Aluminum and other nonferrous metals

will require settings in the 3 to 5 range.

SETUP AND WELDING

Collet Adapter

Collet

Leg Piece

Adjustment Cap

Tension Indicator

10

Foot Piece

WWW.STUDWELDPROD.COM

800-252-1919