Installation and connection

5.3.3

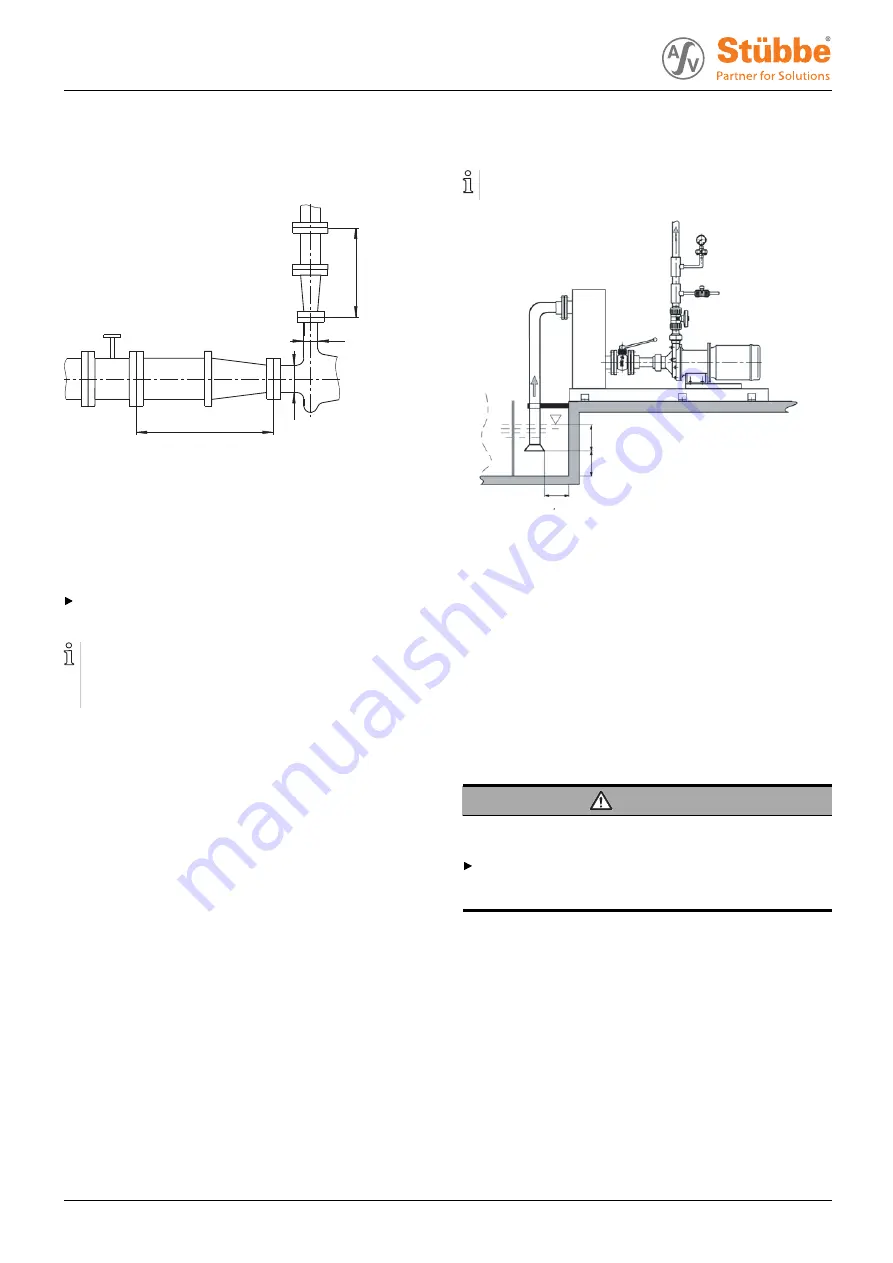

Specifying pipe lengths

C

D

B

A

Fig. 7

Straight pipe lengths in front and after the

pumps (recommended)

A > 5x DNs

B DNs

C DNd

D > 5x DNd

Observe recommended minimum values when installing

the pump.

Suction side: Shorter lengths are possible, but may limit

hydraulic performance data.

Pressure side: Shorter lengths are possible, but may result

in increased noise development.

5.3.4

Provide self-priming container

A self-priming container can be used to make the pump

self-priming.

> 2xDN

> 1,5xDN

> 1,5xDN

1. Select container volumes according to the size of the

pump.

2. Clean containers carefully prior to commissioning or initial

fi

lling.

3. Install a straight section of pipe 5 to 10 x DN as a settling

pipe leading up to the pump intake.

5.3.5

Optimizing changes of cross section and

direction

1. Avoid radii of curvature of less than 1.5 times the nominal

pipe diameter.

2. Avoid abrupt changes of cross-section along the piping.

5.3.6

Discharging leaks

WARNING

Risk of injury and poisoning due to hazardous pumped

liquids!

Safely collect any leaking pumped liquid, then discharge

and dispose of it in accordance with environmental regula-

tions.

1. Provide equipment for collecting and discharging leaking

liquids.

2. Ensure the free discharge of leaking liquids.

16

SHB

BA-2015.12.16 EN

300 486