Installation and connection

5.2

Installing with foundation

NOTE

Material damage due to distortion of base plate.

Position the base plate as follows on the foundation and

attach.

5.2.1

Place pump unit on the foundation

Aids, tools, materials:

–

Anchor bolts (

→

installation drawing)

–

Steel shims

–

Mortar casting compound, no shrinkage

–

Spirit level

1. Lifting the pump unit

2. Hook anchor bolts in the mounting holes on the base plate

from below.

Observe manufacturers information when using the fixing

material.

3. Position the pump unit on the foundation. When doing so

lower the anchor bolts into the prepared anchoring holes.

3

2

1

2

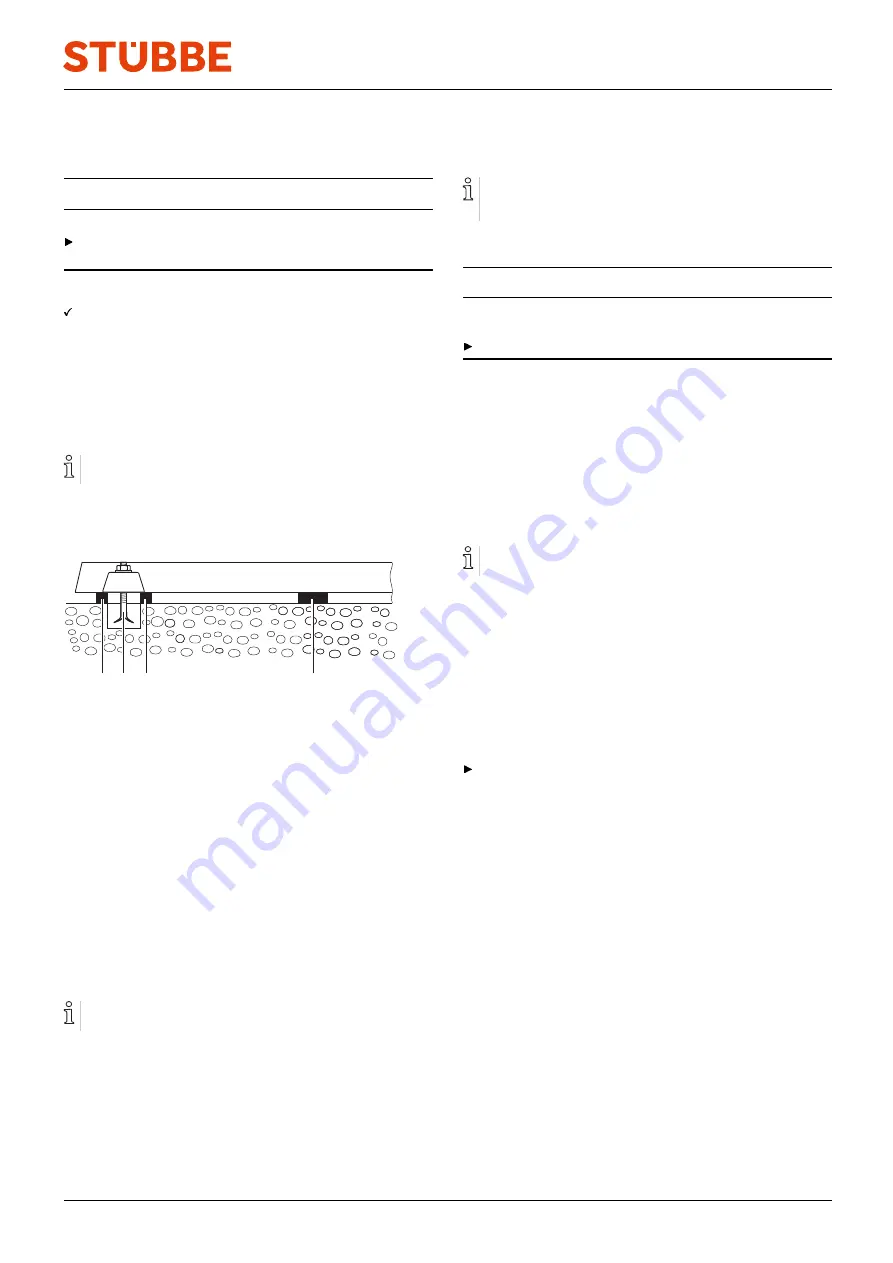

Fig. 5

Installation with foundation

4. Align the pump for height and system dimensions using

steel shims as follows:

–

Arrange steel shims (2) to the left and right of each

anchor bolt (1).

–

If the distance between the anchoring holes is

> 750 mm, then arrange additional steel shims (3) on

each side of the base plate in the center.

5. Ensure that the base plate lies flat against steel shims.

6. Check the permissible height deviation (1mm/m) using a

mechanical spirit level in a longitudinal and a transverse

direction

7. Repeat the procedure until the base plate is correctly

aligned.

5.2.2

Attaching pump unit

Filling the base plate with mortar casting compound

improves dampening properties.

1. Fill the anchoring holes with mortar casting compound.

2. When the mortar casting compound has set, bolt the base

plate at three points to the specified tightening torque.

3. Before tightening the remaining bolts, arrange shims next

to every bolt to even out any irregularities in the mounting

surface.

5.3

Planning pipelines

Water hammer may damage the pump or the system. Plan

the pipes and fittings as far as possible to prevent water

hammer occurring.

5.3.1

Specifying supports and flange connections

NOTE

Material damage due to excessive forces and torques on

the pump.

Ensure pipe connection without stress.

1. Plan pipes safely:

–

No pulling or thrusting forces

–

No bending moments

–

Adjust for changes in length due to temperature

changes (compensators, expansion shanks)

2. Support pipes in front of the pump.

3. Ensure the pipe supports have permanent low-friction

properties and do not seize up due to corrosion.

5.3.2

Specifying nominal widths

Keep the flow resistance in the pipes as low as possible.

1. Ensure nominal suction pipe width is not smaller than the

nominal suction flange width.

–

Recommended flow velocity < 1 m/s

–

Maximum flow velocity = 9 m/s

2. Ensure the nominal pressure line width is not smaller than

the nominal discharge flange width.

–

Recommended flow velocity < 3 m/s

–

Maximum flow velocity = 12 m/s

5.3.3

Designing pipelines

Plan pipes safely:

–

No pulling or thrusting forces

–

No bending moments

–

Adjust for changes in length due to temperature

changes (compensators, expansion shanks)

300 092

BA-2018.08.21 EN

SHM

15