7

INSTALLATION: REFRIG. LINES / STUB-UPS / DRAINS / WIRING DIAGRAMS / VENTILATION

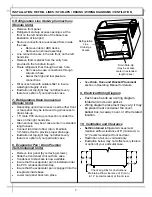

6. Refrigeration Line Stub-Up Connections

(Remote Units)

•

Remove front panel.

•

Refrigerant stub-up access opening is at the

front on the left hand side of the base (see

illustration at top-right).

•

Stub-up connections are accessed from inside

the case.

•

Remove interior ABS decks.

•

Remove fan shroud assembly.

•

Line connections are in the tub front, on the left

hand side

•

Remove foam material from the entry hole

provided in the tub drain trough.

•

Route refrigerant lines through access hole.

•

Run case-to-case connections through

cutouts in base.

•

Sweat the high and low pressure

connections.

•

Fill access hole with suitable filler to insure

watertight integrity of tub.

•

Illustration at top-right may not reflect every

feature or option of your particular case.

7. Refrigeration Drain Connection

(Remote Units)

•

Depending upon drain access needs, either front

or rear panel may be removed to gain access to

drain stub-up.

•

1.5” male PVC stub-up connection is under the

case on the right hand side.

•

Drain stub-up may be at case center in extended

length cases.

•

Connect tub drain to floor drain. Maintain

1/4”-fall per foot to provide proper drainage.

•

Illustration at top-right may not reflect every

feature or option of your particular case.

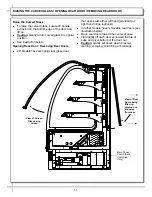

8. Evaporator Pan / Drain Position

(Self-Contained Units)

•

Remove rear panel (by removing screws).

•

Slide the Condenser Unit out from case.

•

Condenser Unit access is now available.

•

Insure that the evaporator pan is installed under

the PVC condensate drain trap.

•

Insure that the evaporator pan is plugged into the

receptacle inside base.

•

Lower rear panel back into place.

Refrigeration

Line

Stub-Ups

Access

Drain Stub-Up

(may be at case

center in extended

length cases)

10. Ventilation and Clearance

•

Self-Contained

refrigerated cases must

maintain airflow clearance of 6” (minimum) to

12” (recommended) at front and rear.

•

Restriction of air can void warranty.

•

Illustration below may not reflect every feature

or option of your particular case.

Check air grilles for obstructions.

Maintain airflow clearance of 6” (min.)

to 12” (recommended) at front & rear.

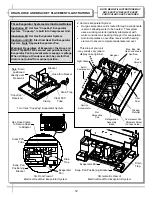

9. Electrical Wiring Diagram

•

Each case has its own wiring diagram

folded and in its own packet.

•

Wiring diagram placement may vary; it may

be placed near condenser fan cover,

ballast box, raceway cover, or other related

location.

•

See

Drain, Hose and Bracket Placement

section in Operating Manual for details.