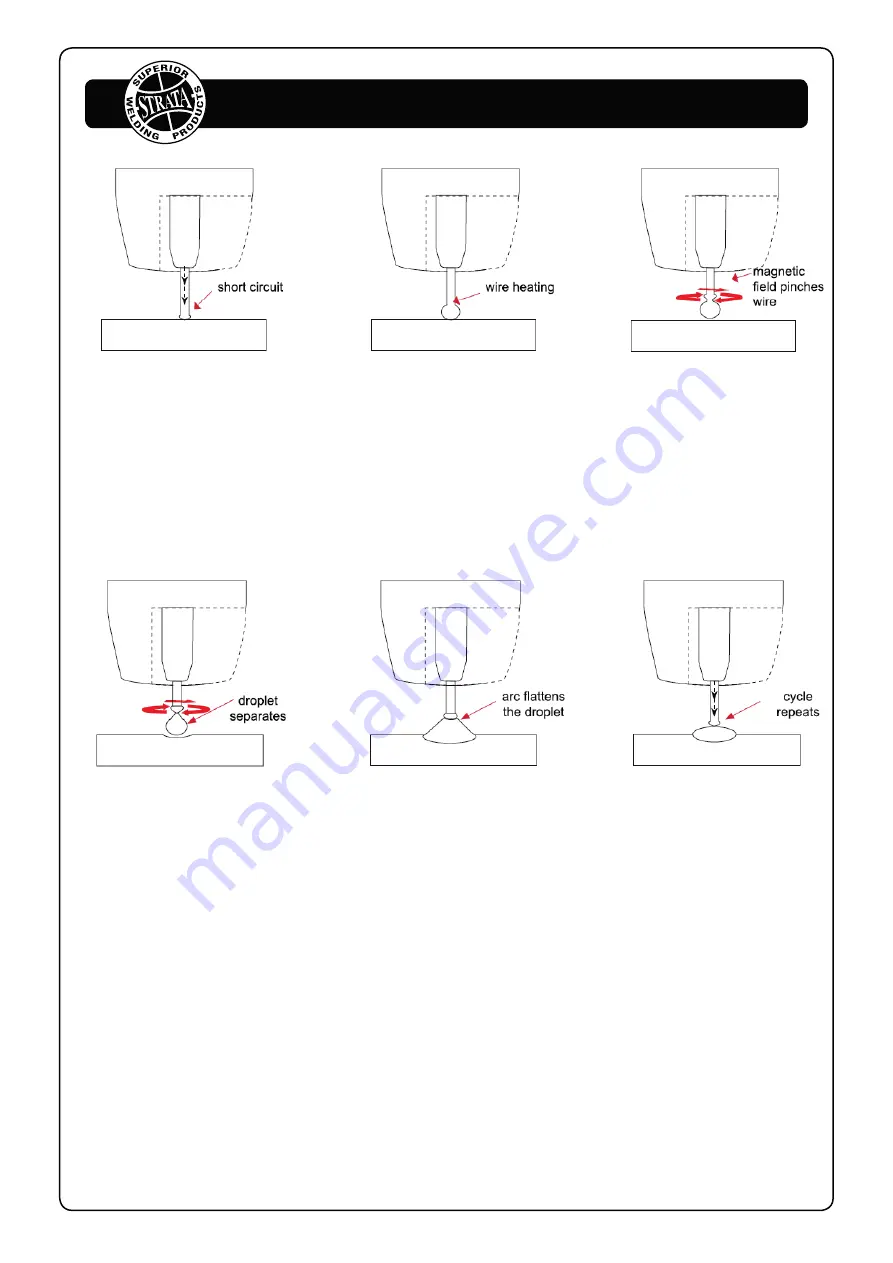

The pinch causes the forming

droplet to separate and fall

towards the now creating

weld pool.

An arc is created at the

separation of the droplet and

the heat and force of the arc

flattens out the droplet into

the weld pool. The heat of the

arc melts the end of the wire

slightly as it feeds towards

the base metal.

The wire feed speed

overcomes the heat of the

arc and the wire again

approaches the work to

short circuit and repeat the

cycle.

Basic MIG Welding

Good weld quality and weld profile depends on gun angle, direction of travel, electrode extension

(stick out), travel speed, thickness of base metal, wire feed speed and arc voltage. To follow are

some basic guides to assist with your setup.

Gun Position - Travel Direction, Work Angle:

Gun position or technique usually refers to how

the wire is directed at the base metal, the angle and travel direction chosen. Travel speed and work

The wire approaches the work

piece and touches the work

creating a short circuit between

the wire and the base metal,

because there is no space

between the wire and the base

metal there is no arc and

current flows through the wire.

The wire cannot support all

the current flow, resistance

builds up and the wire

becomes hot and weak and

begins to melt.

The current flow creates a

magnetic field that begins

to pinch the melting wire

forming it into droplet.

34

www.strata.co.nz

ADVANCEMIG 255C