15

15 Machine components

Feed Motor

The feed motor can be turned ON or OFF, either manually via the head unit, or automatically by the

remote mounted spring finger switch which can be fitted to the linkage or the implement. The feed motor

must be switched ON via the head unit for the spring finger switch to work automatically.

Spring Finger Switch

The switch should be mounted to a suitable place on the implement or linkage of the tractor, thus

deflecting the spring, and automatically switching the feed motor off or on accordingly as the circuit is

made or broken.

Position the finger switch so that the tip of the spring comes into contact with the moving part of the

implement or linkage when lifted out of work, and remains deflected until the implement is lowered back

into work. NOTE. Ensure that there is sufficient and positive deflection on the spring to prevent accidental

switching ON or OFF if the implement moves slightly up or down in work.

The standard wiring as supplied for this switch is when the spring is at rest, the feed motor will run

normally. If required, the switch can work in the opposite mode by changing the position of the 2

wires inside the switch so that the switch is out of work when the sprung is at rest.

To change over remove the PVC cover plate held in position with the retaining screw to access the wiring

terminals. Remove the 2 wires from terminals 13 and 14 and re-connect to terminals 21 and 22

(nearest the gland nut) then re-fit the PVC cover plate. (

NOTE

the area meter also stops when the feed

motor stops)

12v Disc Motor

The disc motor can be switched on and off and the disc speed adjusted on the instrument panel

GPS Sensor

Small and compact with integrated magnetic base for ease of fitting to tractor cab or suitable mounting

position. Fitted with a 5m lead which plugs into the i-Con instrument connector cable

Hoper Level Sensor

The instrument will alarm once the product in the hopper falls below the level of the sensor

Main Power Cable

The power cable should connect directly to the vehicle battery posts to ensure adequate 12v supply to

the disc motor. The in-line is 25 amp.

This 7m power cable connects from the battery to the power input flylead on the machine. .

Instrument Lead

The 6m instrument lead connects to the junction box mounted on the machine, and runs to the i-Con

instrument panel connector lead in the tractor cab.

NOTE

Extension power and instrument cables are available if required.

Please contact your local Stocks AG dealer for more information.

21

14

22

13

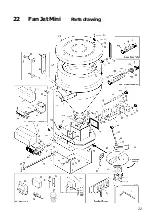

Содержание Fan Jet Mini i-CON 130

Страница 22: ...22 22 Fan Jet Mini Partsdrawing...