11

11-1 Clearing a blockage

Switch off the main power switch on the control panel

Ensure the parent machine is stationary, switched off, and parked on level ground

Ensure the main power switch on the control panel is off and unplug the 2 core power supply cable from the

control box or disconnecting the power cable from the vehicle battery.

Ensure appropriate personal protection equipment is worn for the product being applied

Ensure any product removed is put back into its original container

Care to be taken not to spill any product that could contamination the environment.

Empty the hopper of any remaining product

11-2 Hopper removal

Removing the hopper for cleaning and maintenance

Ensure the hopper is completely empty and free from any product residue

Ensure appropriate personal protection equipment is worn for the product being applied

Release the rubber lid retaining straps and remove the

lid. The hopper can then be lifted away after removing

the retaining plate(s) from within the hopper by re-

leasing the M8 external fixing nuts and washers.

NOTE

When replacing he hopper ensure the Gasket fit-

ted under the base of the hoper is in good order

Replace if damaged; part number FJ017S

11-3 Storage

Disconnect the power supply by unplugging the power

cable or removing the fuse in the power cable if storing

the machine for long periods.

It is the responsibility of the operator to ensure the

hopper is empty after each and use and cleaned

thoroughly before storage.

Store in dry conditions to protect the machine and control system from moisture

Always clean and spray electrical connectors with a moisture repellent spray when not in use for long

periods.

11-4 Optional PVC Waterproof Covers

Heavy duty White PVC cover fitted with eyelets and bungie cord for easy attachment

65L Waterproof PVC Cover

Part No. LC65

130L Waterproof PVC Cover

Part No. LC130

Available through your local Stocks AG dealer

11-5 Disposal

Ensure that any persons handling the machine are aware that the machine may have been used

to apply toxic chemicals and so the appropriate personal protection equipment should be worn.

Ensure the hopper contents have been removed and any toxic residue removed and put back into a sealed

contained or disposed of in accordance with the manufacturers guidelines to eliminate any possible

contamination of others or the environment.

Always adhere to the local disposal regulations paying

particular attention to the plastics, rubber, and electrical components

.

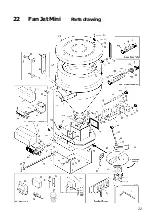

Содержание Fan Jet Mini i-CON 130

Страница 22: ...22 22 Fan Jet Mini Partsdrawing...