5

Maintenance

Maintenance safety instructions

Hydraulic

1

Check the hydraulic cylinder, piston for damage noise

and leakage.

•

•

•

2

Check the hydraulic connections and hose for damage

an leakage.

•

3 Check the hydraulic oil level, refill if necessary.

•

4 Replace the hydraulic oil after every 1500 working

hours or 12 months.

•

5

Check the function of the pressure relief valve (1500kg

+0/+10%).

•

Mechanical system

6 Check the forks for deformation and cracks.

•

7 Checks the chassis for deformation and cracks.

•

8 Check if all screws are fixed.

•

9 Check the push rods for deformation and damages.

•

10 Check the gearbox for noise and leakage.

•

11 Check the wheels for deformation and damages.

•

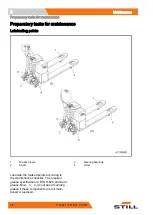

12 Lubricate the grease nipples.

•

•

•

Electrical system

13 Check the electric wiring for damage.

•

14 Check the electric connections.

•

15 Test the emergency switch function.

•

16 Check the electric drive motor for noise and damages.

•

17 Test the display.

•

18 Check if the correct fuses are used.

•

19 Test the warning signal.

•

20 Check the contactors.

•

21 Check function and mechanical wear of the direction

switch.

•

22 Check the electrical system of the drive motor.

•

Battery

23 Check the battery voltage.

•

24 Check the terminals for corrosion and damage.

•

25 Check the battery housing for damages.

•

Battery Charger

56

1133 801 16 01 EN - 11/2018

Содержание ECU 15C

Страница 1: ...Original instructions Electric pallet truck ECU 15C 0138 1133 801 16 01 EN 11 2018 ...

Страница 2: ......

Страница 8: ......

Страница 9: ...1 Introduction ...

Страница 23: ...Introduction 1 Residual risks 1133 801 16 01 EN 11 2018 15 ...

Страница 28: ...1 Introduction Residual risks 20 1133 801 16 01 EN 11 2018 ...

Страница 29: ...2 Safety ...

Страница 41: ...3 General views ...

Страница 45: ...4 Operation ...

Страница 61: ...5 Maintenance ...

Страница 70: ...5 Maintenance Trouble shooting 62 1133 801 16 01 EN 11 2018 ...

Страница 71: ...6 Technical data ...

Страница 77: ......

Страница 78: ...STILL GmbH 1133 801 16 01 EN 11 2018 ...