n

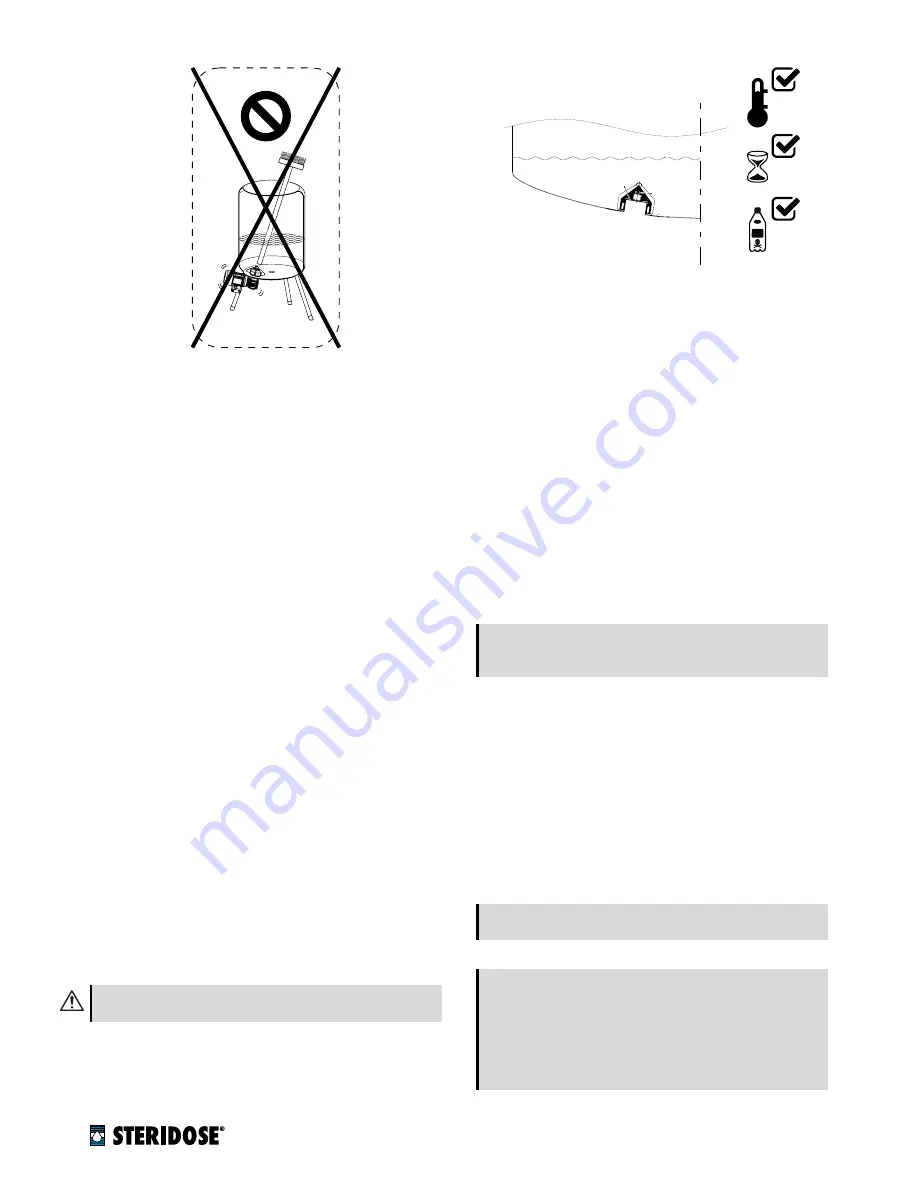

Figure 8

Never insert foreign objects in the vessel when

the mixer is operational.

To avoid dry running the speed has to be adjusted in

accordance to the level in the tank. This will depend on

the following:

• The diameter of the tank.

• The shape of the bottom of the tank.

• The viscosity; as viscosity increases, the flow through

the impeller decreases.

The above are process and installation parameters, not

mixer parameters. Specific maximum speed for an appli-

cation is not dictated by the mixer, but by the combination

of mixer, tank, process fluid and purpose of mixing.

4.5. Further operational advice

The impeller is factory cleaned prior to delivery. How-

ever, before it is put into service it must be cleaned in an

appropriate manner so that it is free from foreign parti-

cles, followed by CIP and/or SIP cycles as required by the

application.

The operational parameters are pre-set in the control

box (applies only to Steridose-supplied control boxes). In

extreme working conditions, uncoupling of the magnetic

coupling can occur, i.e. the motor rotates, but not the im-

peller. To avoid any uncoupling of the magnetic coupling,

the acceleration time (ramp up) and the maximum rpm

should be adjusted to conform to the specific application.

For a Sterimixer/Sanimixer supplied without a control

box, soft manual start of the motor is required to prevent

the magnetic coupling becoming uncoupled. A suitable

acceleration time up to the maximum rpm can be anything

from ten seconds to a couple of minutes depending on the

application.

CAUTION:

Never insert foreign objects in the vessel

when the mixer is operational.

4.5.1. Cleaning

guidance

for

SMA-type

impeller

equipped Sterimixers

The Sterimixer is designed for optimum performance in

cleaning in place (CIP) without any need for dismounting.

n

Figure 9

Succesful cleaning of the impeller relies on a

combination of the self-cleaning flow through design of the

SMA-type impeller, the cleaning-agent used and respecting

the prescribed time and temperature.

The flow channels in the impeller provide a process fluid

flow through the bearings. In order to achieve this, the

impeller should be covered with fluid and rotated at a

certain minimum speed. The flow of the process fluid

through the flow channels is very much determined by

the rotational speed of the impeller.

The result of the cleaning is dependent on many param-

eters such as temperature, time, and chemical composition

of the cleaning agent, mechanical conditions, speed and

the type of product to be removed.

The cleaning usually consists of several cycles e.g. pre-

rinse, cleaning with base and/or acid cleaning agents,

main rinse following acid or base cleaning, and a final

rinse.

+

NOTICE:

To achieve the optimal cleaning effect the

impeller should be covered with cleaning agent and

rotating.

Example of CIP procedure for SMA-type impeller:

1. Drain the vessel of process fluid.

2. Close the outlet and fill with cleaning agent having

the fluid level above the impeller with at least 150 -

200 mm.

3. A suitable speed is approximately 300 rpm with filled

vessel (depending on the size).

4. Normal cycle time is 5 - 20 minutes.

+

NOTICE:

The exact operational conditions for CIP must

be validated for each individual application.

+

NOTICE:

The cleaning method described above does

not remove any magnetic particles. Due to the strong

magnets inside the impeller all magnetic particles will

be stuck inside the impeller. To have these removed,

the impeller must be removed and cleaned separately.

Magnetic particles stuck to the impeller may cause dis-

colouration of the impeller surface.

www.steridose.com

Installation & Operation

|

9

Содержание Sanimixer

Страница 15: ...www steridose com Installation Operation 15 ...