Digital Microstep Driver DM556N

7

(4). t4: Low level width is not less than 2.5µs.

3.5 Wiring Requirements

(1). In order to prevent the driver from being disturbed, it is recommended to use a twisted-pair

shielded cable and the shield layer grounded (single-ended ground). Make sure the connection is

true ground, otherwise the interference may be more serious.

(2). The control signal lines and the motor lines are not allowed to be side by side, preferably

separated by at least 10 cm. Otherwise, the motor electromagnetic noise easily interfere with the

control signal, causing the motor to be inaccurately positioned and the system is unstable.

(3). If one power supply is used for multiple drivers, parallel mode should be used at the power

supply, and it is not allowed to connect to another driver at the driver’s pin.

(4). It is strictly forbidden to plug and unplug the driver motor line terminal. When the energized

motor stops, there is still a large current flowing through the coil. Pulling out the motor line

terminal will cause a huge instantaneous induced electromotive force to burn the driver.

(5). It is strictly forbidden to add tin to the wire lead and then connect the terminal. Otherwise, the

terminal may be damaged due to the contact resistance becoming large and overheating.

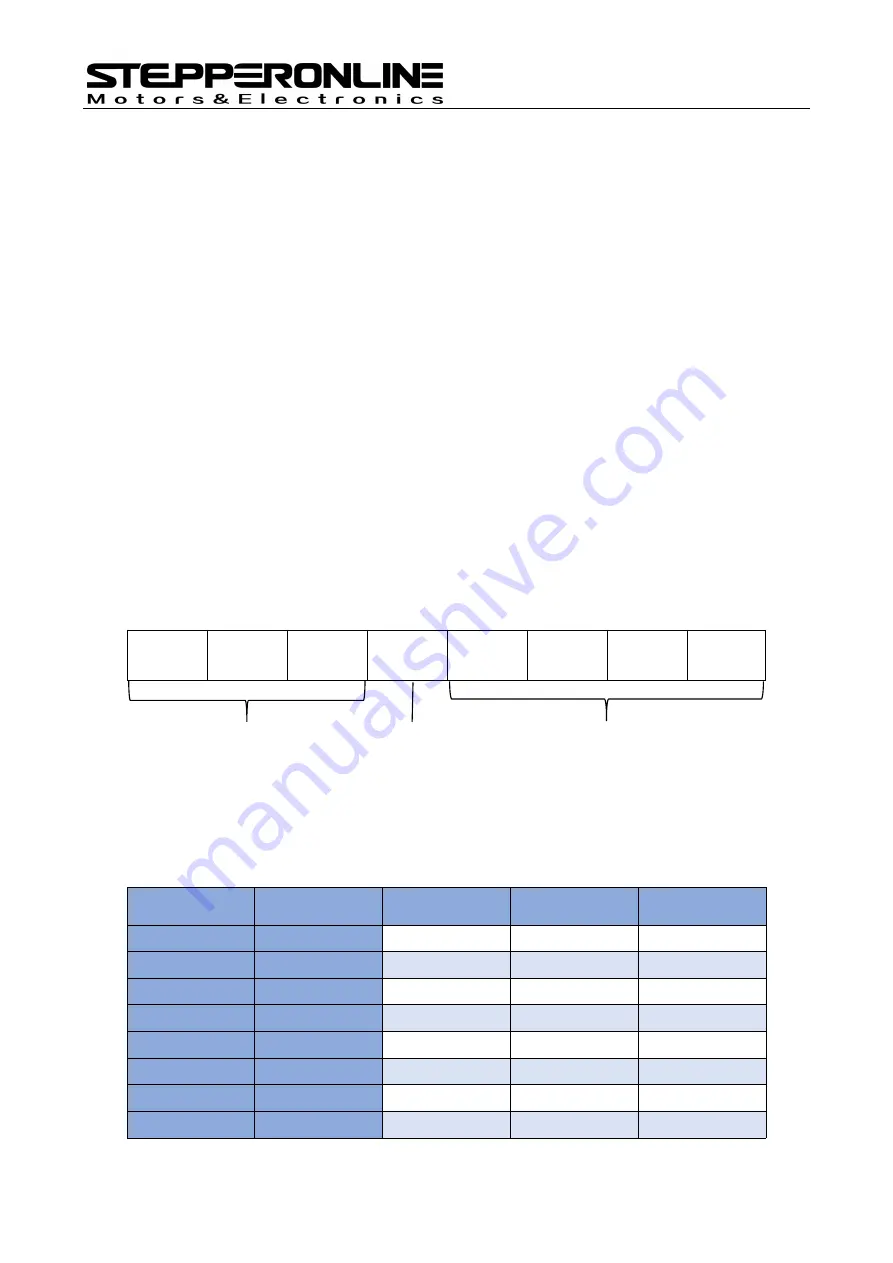

4. DIP Switch Setting

The DM556N driver uses a 8-bit DIP switch to set operating current, standstill current, and

microstep resolution. The detailed description is as follows:

SW1

SW2

SW3

SW4

SW5

SW6

SW7

SW8

Figure 5: DIP switch setting

4.1 Operating Current Setting

The first three bits (SW1, SW2, SW3) of the DIP switches are used to set the operating current of the

motor. Select the setting that is closest value to the motor as required current.

Peak Current RMS Current

SW1

SW2

SW3

1.4A

1.0A

ON

ON

ON

2.1A

1.5A

OFF

ON

ON

2.7A

1.9A

ON

OFF

ON

3.2A

2.3A

OFF

OFF

ON

3.8A

2.7A

ON

ON

OFF

4.3A

3.0A

OFF

ON

OFF

4.9A

3.5A

ON

OFF

OFF

5.6A

4.0A

OFF

OFF

OFF

Operating current

Standstill current

Microstep resolution