SR200

Specifications subject to change

2.5

in the holder. It is advisable to connect the lead to the display-traverse unit first and then the

pick-up. To connect the pick-up to the display-traverse unit: the pick-up has 2 threaded ends

with location pins. Insert the location pin securely into the SR200 body and tighten the threaded

collar.

When the extension rod is used, the short pick-up lead is not required and the end of the rod

itself is inserted into the holder.

Pick-up:

The pick-up is a variable inductive type transducer, which is supported on the

surface to be measured by a skid, a curved support projecting from the underside of the pick-

up in the vicinity of the stylus. As the pick-up traverses across the surface, movements of the

stylus relative to the skid are detected and con-verted into a proportional electrical signal. The

radius of curvature of the skid is much greater than the roughness spacing. This enables it to

ride across the surface almost unaffected by the roughness, and provide a datum representing

the general form of the surface. Even so, where the waviness is widely spaced it will be

necessary to use the pick-up with shoe, in conjunction with the 2.5mm (0.1in) cut-off.

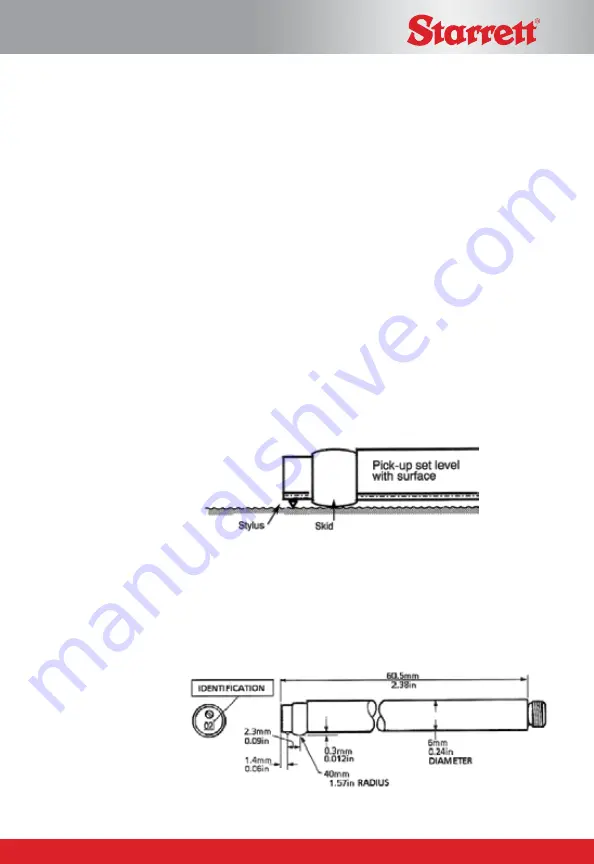

Figure 5: the pickup is supported on the workpiece by the skid

There are several different types of pickup available designed for different applications, details

are given in the Accessories section of this handbook. They differ only in the stylus tip radius,

the dimensions of the housing or position and the shape of the skid. The stylus material in all

the pickups is diamond for low wear. The skids of the standard pickups are of red ruby.

Figure 6. Standard pick-up dimensions

Rapp Industrial Sales 724 789-7853