Service Manual – Treadmills: E-Series

•

P-Series

64

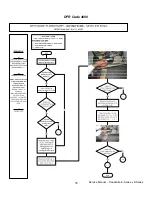

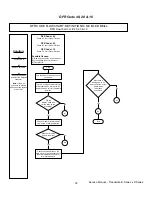

Slipping Running Belt

Slipping is the term that many people use when a running belt stops moving for a split second, but the

motor, possibly the head roller, keeps moving.

Possible causes for a slipping running belt:

•

Loose drive belt

•

Worn running belt

•

Loose running belt

To identify the cause of a slipping running belt, follow these troubleshooting steps:

1. Lift the motor shroud.

2. With the motor shroud lifted, start walking on the treadmill. Watch the head roller.

•

If running belt slips and the head roller stops moving. This indicates the drive belt is loose.

Tighten the drive belt.

•

The running belt slips but the head roller keeps moving. There are two possible causes.

1. The running belt is worn. Check the condition of the running belt. Feel the underside

of the belt. If the belt feels glazed/ glossy in the center, it is worn and should be

replaced. The underside of the running belt should have a rough canvas feel to it.

2. The running belt is loose. Turn each tail roller screw ¼ turn clockwise. Check to see

if the running belt continues to slips. If the running belt continues to slip, tighten the

tail roller screws another ¼ turn clockwise. Keep following this procedure until the

running belt stops slipping. Note: If the running belt continues to slip after the tail

roller screws have been tightened one full turn clockwise, call Star Trac Customer

Support for more assistance.

Many people assume only a loose running belt causes slipping, and will attempt to correct the

problem by adjusting the tail roller screws. This may cause damaged to the running belt by over

tensioning.

Содержание Pro Tread AC 7600

Страница 47: ...Service Manual E TR and E TRi 45 SOFTWARE MCB...

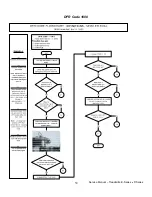

Страница 59: ...Service Manual E TR and E TRi 57 DFR Code 1000000 100000 and 10000...

Страница 60: ...Service Manual Treadmills E Series P Series 58 DFR Code 4000...

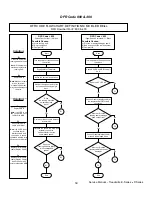

Страница 61: ...Service Manual Treadmills E Series P Series 59 DFR Code 1000...

Страница 65: ...Service Manual Treadmills E Series P Series 63 DFR Remaining Codes...

Страница 67: ...Service Manual AC Pro Tread 7600 7700 65 This page intentionally left blank...