SRP 2240 / 3860

User

Manual ◄ 7

SAFETY

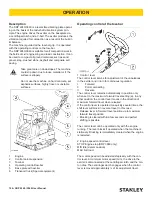

Machine control

Operating devices which adjust themselves automatically when

released in normal use, must not be locked.

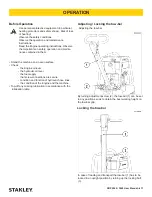

Check protective devices and brakes for proper functioning prior

to operation.

When reversing, particularly on the edges and banks of ditches,

as well as in front of obstacles, the machine operator cannot fall

or be crushed.

Always keep a safe distance away from the edges and banks

of ditches and refrain from any actions which could cause the

machine to topple over!

Always control the machine, so that hand injuries through hard

objects are avoided!

Always ascend slopes carefully in a direct path.

Reverse up steep slopes to prevent the machine from toppling

over on to the machine operator.

If faults on the safety devices or other faults detrimental to the

safe operation of the machine are noticed, operation of the ma-

chine must be stopped immediately and the faults remedied.

When undertaking compaction work in the vicinity of buildings or

above pipelines and similar, check the effect of the vibrations on

the buildings and pipes and stop compaction work if necessary.

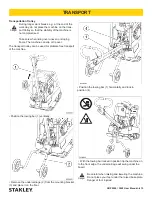

Parking the machine

Park the machine on a firm and level surface.

Shutdown the drive and secure it to prevent accidental move-

ment and unauthorized use. If available, close the fuel valve. Do

not place or store equipment with integrated moving gear on the

chassis. The moving device is intended only for transportation

purposes.

Filling Fuel

Only fill fuel by switched-off motor. No open fire, do not smoke.

Do not spill any fuel, collect discharging fuel in a suitable

container, prevent fuel from seeping into the soil.

Ensure that the filler cap is tight.

Leaky fuel tanks constitute an explosion hazard and must there-

fore be replaced immediately.

Maintenance and repairs

Observe the maintenance, inspection and adjustments and inter-

vals specified in the operating instructions, as well as the informa

-

tion for part replacement.

Maintenance work must be undertaken only by qualified and

authorised persons.

Maintenance and repairs only by switched-off drive.

Only carry out maintenance and repairs when the machine is

parked on a firm and even surface and is secured to prevent it

from rolling.

When changing larger assemblies and individual components,

only use suitable and perfectly functioning hoisting and lifting

gears with suitable loading capacity. Attach and secure parts on

hoisting carefully!

Spare parts must comply with the technical requirements of the

manufacturer. Therefore only use original spare parts.

Hydraulic lines must previously be rendered pressureless, before

working on them. Hydraulic oil discharging under pressure can

cause serious injuries.

Work on hydraulic devices must be undertaken only by persons

with a special knowledge of hydraulics and the necessary

experience!

Do not adjust pressure relief valves.

Drain hydraulic oil at operating temperature—caution risk of

scalding!

Collect discharging hydraulic oil and dispose of the same in an

environmentally-friendly manner.

Do not start the motor when hydraulic oil has been drained off.

After completing all work (by pressureless system), inspect all

connections and bolted connections for leaks.

Inspect all hoses and bolted connections for leaks at regular

intervals and externally visible damage! Rectify any damage

immediately.

Replace externally damaged hydraulic hose lines at regular

intervals (depending on time used), even when no safety-relevant

faults are visible.

Before working on the electrical system of the machine,

disconnect the battery and insulate by covering or remove.

Inspect the electrical equipment of the machine at regular inter-

vals. Faults such as loose connections, worn or scorched cables

must be immediately eliminated.

During transport, secure the battery to prevent it from tilting, short-

circuit, slipping and damage.

Dispose of used batteries in a proper manner. Do not place any

tools on the battery.

Handling acid-batteries

Transport filled batteries upright to prevent acid spillage.

Keep away from sparks, open fire and other sources of ignition.

Avoid contact of acid with skin and clothing. In case of contact,

wash off acid immediately with clear water and go to medical

institution.

Properly refit and inspect all protective devices after maintenance

and repairs.

Testing

Road rollers, trench rollers and vibrating plates must be tested for

safety by an expert depending on the particular application and

operating conditions as required, however at least once a year.

Disposal of the machine after finish of its service life

At disposal of the machine after finish of its service life, the owner

is obliged to comply with national regulations and laws on wastes

and protection of environment. Therefore we recommend in

such cases to contact the following:

• professional specialized companies engaged in such activities

and having the relevant certificate

• the manufacturers or contracting service organizations autho-

rized by him.

The manufacturer is not responsible for damages to health of

owners neither for damages to the environment in events of failing

to comply with above mentioned hygienic and ecological

principles.

Содержание SRP 2240

Страница 27: ...SFP 2240 3860 User Manual 27 NOTES...