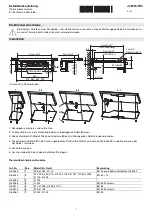

EXPLODED VIEW

11

1.

Bonnet

2.

Bonnet Door

3.

Spin Valve

4.

Back Outlet Spigot

5.

Top Flue Spigot

6.

Hot Plate Cup (LH)

7.

Hot Plate Cup (RH)

8.

Hot Plate

9.

Cleaning Cups

10.

Hot Plate Cord

11.

Hob

12.

Sheet Iron Back (LH)

13.

Back Sealing Plate

14.

Sheet Iron Back (RH)

15.

Oven Back Insulation

16.

Flue Back

17.

Boiler Back Insulation

18.

Oven Back

19.

Hob Protection Plate (Large)

20.

Hob Protection Plate (Small)

21.

Sheet Iron Side

22.

Side Insulation

23.

Oven End Flue Top

24.

Back Flue Guide

25.

Damper Guide (RH)

26.

Direct Damper

27.

Damper Guide (LH)

28.

Oven End Flue Bottom

29.

Oven Side (RH)

30.

Front Flue Guide

31.

Steam Escape

32.

Oven Damper

33.

Oven Top

34.

Oven Shelf Cast Iron

35.

Oven Shelf Sheet Iron

36.

Oven Bottom

37.

Mild Steel Glass Lined Boiler

38.

Plastic Boiler Plugs

39.

Oven Side Brick M3-980

40.

Oven Side (LH)

41.

Boiler Zest

42.

Fire Box LHS Top Brick

43.

Fire Box LHS Bottom Brick

44.

Sham Cheek

45.

Fire Box Front Top Brick

46.

Grate

47.

Fire Box Base Insert

48.

Fire Box Base

49.

Ash Tray

50.

Ashpit Back

51.

Ashpit Side (LH)

52.

Ashpit Bottom

53.

Ashpit Side (RH)

54.

Fall Bar Frame Back

55.

Stay Rods

56.

Fall Bar

57.

Fall Bar Frame Front

58.

Fire Box Front Bottom Brick

59.

Serial Number Plate

60.

Front

61.

Towel Rail Bracket (RH)

62.

Towel Rail

63.

Oven Door Panel Sheet Iron

64.

Fire Door Lining

65.

Fire Door Insulation

66.

Fire Door Rope

67.

Fire Door Insulation Panel

68.

Oven Door Rope

69.

Oven Door Insulation

70.

Fire Door

71.

Ashpit Door Rope

72.

Ashpit Door

73.

Ashpit Spin Valve

74.

Oven Door

75.

Thermometer

76.

Door Handles (3)

77.

Cleaning Door Clip

78.

Cleaning Door

79.

Towel Rail Bracket (LH)

80.

Base

81.

Flue Check

82.

Front Plinth (Sheet Iron)

83.

Side Legs (2) Sheet Iron

84.

Poker

85.

Scraper

86.

Cast Iron Cup Lifter

87.

Non Boiler Back Top

88.

Non Boiler Back Bottom

89.

Non Boiler Brick

90.

15K Central Heating Boiler

91.

21K Central Heating Boiler

92.

Pipe

}

93.

Bend

} - Special Order

94.

Cleaning Brush

95.

Optional Legs

Содержание Mourne

Страница 13: ...12 MOURNE EXPLODED VIEW ...