NOTICE:

This pump is designed to power automatic swimming pool

cleaners or other systems requiring high pressure at relatively low flow

rates. Operating the pump with open discharge or without flow restric-

tion could overload the pump motor. Operate the pump only while con-

nected to the system in which it is designed to operate. When installed

for automatic time clock operation on a swimming pool cleaner system,

be sure that clock is set so that the cleaner booster pump comes on only

when the main circulation system for the pool is operating. Failure to

coordinate the “on” cycles could provide insufficient flow to the cleaner

booster pump, resulting in failure of the booster pump.

INSTALLATION

Only qualified, licensed personnel should install pump and wiring.

Pump mount must:

Be solid - Level - Rigid - Vibration free. (To reduce vibration and pipe

stress, bolt pump to mount.)

Allow pump suction inlet to be as close to pool return line as possible.

Allow use of short, direct suction pipe from tee on return line (See Fig. 1).

Allow for gate valves in suction and discharge piping.

Have adequate floor drainage to prevent flooding.

Be protected from excess moisture.

Allow adequate access for servicing pump and piping.

NOTICE:

Use Teflon tape or Plasto-Joint Stik

1

for making all threaded

connections to the pump. Do not use pipe dope; pipe dope will cause

stress cracking in the pump.

NOTICE:

Pump suction and discharge connections have molded in

thread stops. DO NOT try to screw pipe in beyond these stops.

4

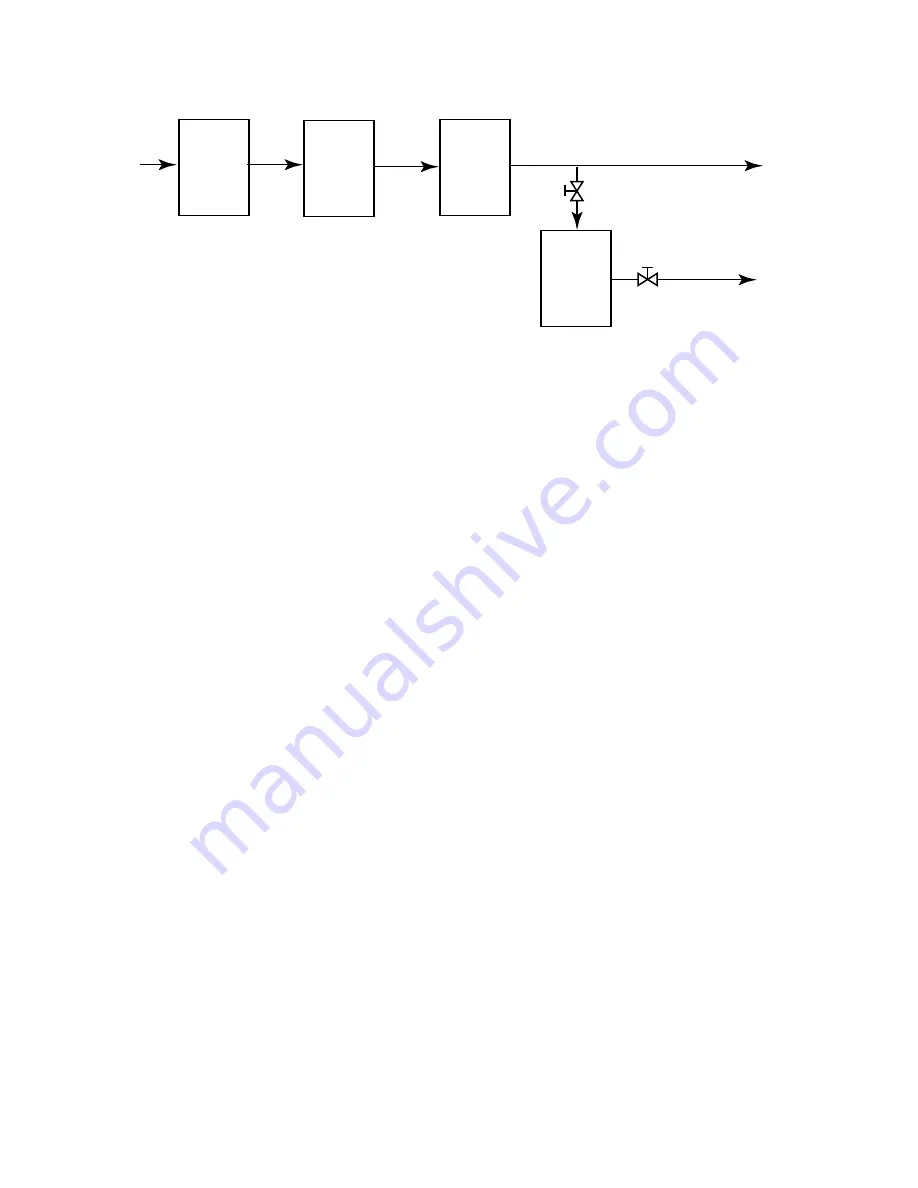

From

Pool

Suction

Main

Pool

Pump

Filter

Heater

(If used)

Pool

Booster

Pump

To

Pool

Return

To

Pool

Cleaner

POOL RETURN

LINE

GATE

VALVE

3/4" RIGID OR NON-COLLAPSIBLE

FLEXIBLE PLUMBING

FIGURE 1