14

General

CV/EN (1009) 5.3

2.3

Serial number

Serial number of the pump or pump unit are shown on the name plate off the pump and

on the label on the cover of this manual.

2.4

Applications

• In general, this pump can be used for thin, clean or slightly polluted liquids. These

liquids should not affect the pump materials.

• The maximum allowed system pressure and temperature and the maximum speed

depend on the pump type and the pump construction. For relevant data see paragraph

2.6 "Application area".

• Further details about the application possibilities of your specific pump are mentioned

in the order confirmation and/or in the data sheet enclosed with the delivery.

• Do not use the pump for purposes other than those for which it is delivered without

prior consultation with your supplier.

Using a pump in a system or under system conditions (liquid, working

pressure, temperature, etc.) for which it has not been designed may hazard

the user!

2.5

Construction

The pump has a modular design. The main components are:

• Pump casing/impeller/suction bend

• Shaft sealing

• Self-priming unit

• Bearing

• Lantern construction

• Foot pads

The pumps are available in 3 bearing groups, meaning that bearing and shaft sealing are

divided into 3 groups. Furthermore, the pumps have been standardized in 5 groups

featuring the same connection for pump cover and bearing pedestal, depending on the

nominal impeller diameters. The pump covers are clamped between the pump casing

and bearing bracket.

2.5.1

Pump casing/impeller/suction bend

These are the parts that get into contact with the pumped liquid. For each individual

pump type there is only one construction of the pump casing and the impeller. The pump

casing and the suction bend are available in cast iron and in bronze, the impeller in cast

iron, bronze and aluminium bronze. The pump shaft is available in alloyed and stainless

steel. With the available materials the pumps can be supplied in a construction suitable

to pump sea water. The square suction bend has been designed in such a way that

resistance is low an that all the same a low position of the pump in relation to the floor is

possible. The pump types 200-200, 250B-315 have a fabricated suction bend. The

suction bend can be mounted in different positions in relation to the discharge flange.

This offers a large number of mounting possibilities.

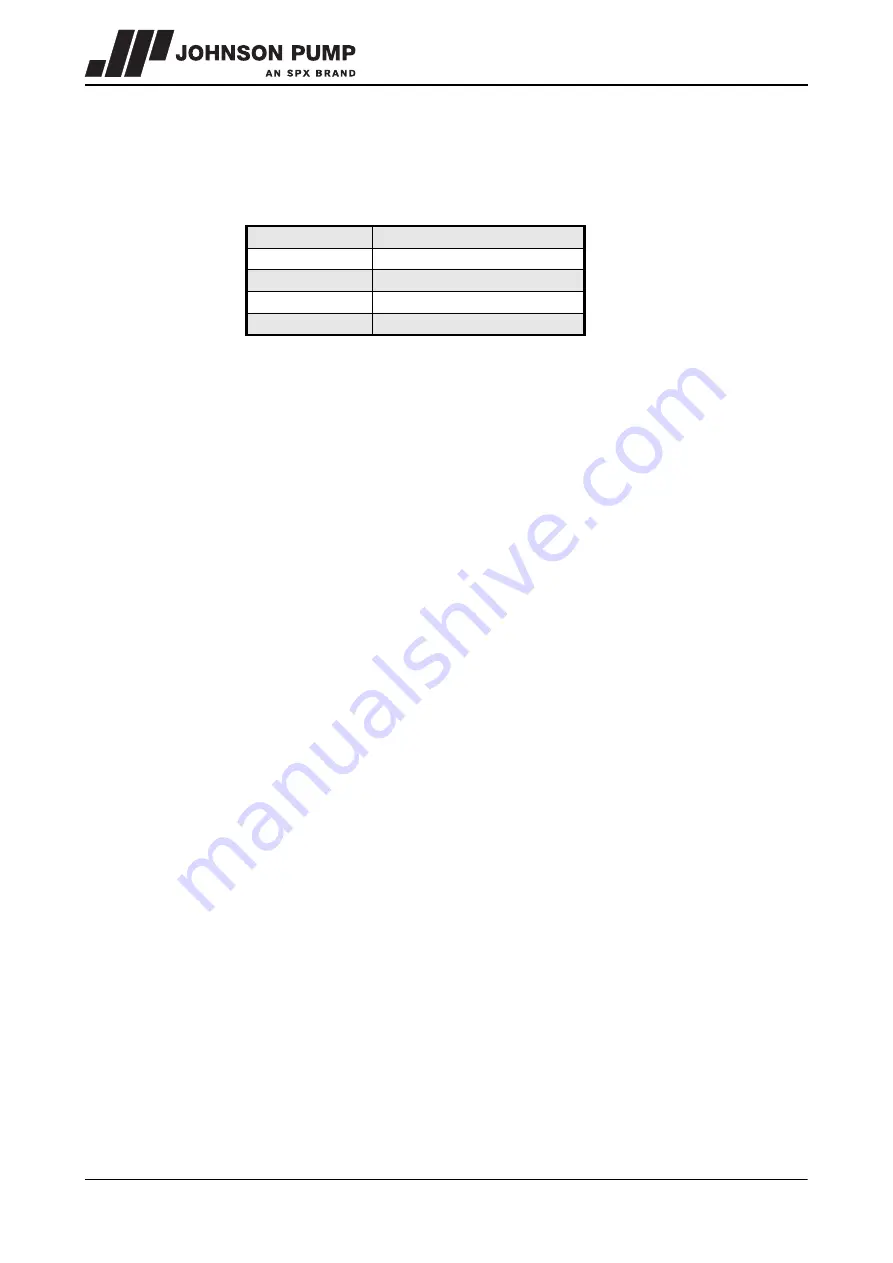

Example:

01-1000675A

01

year of manufacture

100067

unique number

5

number of pumps

A

pump with motor

B

pump with free shaft end

Содержание Johnson Pump CombiPrime V

Страница 3: ...2 EC EN 1001 5 1...

Страница 5: ...4 CV EN 1009 5 3...

Страница 9: ...8 CV EN 1009 5 3...

Страница 49: ...48 Disassembly and assembly CV EN 1009 5 3...

Страница 63: ...62 Dimensions CV EN 1009 5 3...

Страница 65: ...64 Parts CV EN 1009 5 3 9 2 Pump 9 2 1 Sectional drawing Figure 29 Sectional drawing...

Страница 81: ...80 Technical data CV EN 1009 5 3...

Страница 85: ...84 ORDFORM 0804 3 1 EN...