25

MISC

-

1: DWYER FLOW METER SERVICE

The mechanical flow meter, can be opened for cleaning if it becomes difficult to read or

if the little ball gets stuck.

The flow meter will come completely apart for cleaning;

1. First remove the meter from the panel (which may require the plumbing fittings to

be removed) by removing the brackets that hold it to the gauge panel.

2. On the very top of the meter is a clear plastic key that slides into place holding the

top cap of the assembly in place. Use a small flat bladed screwdriver to pull the key

out..

3. Hold the meter upright (or the ball will fall out) and then lever the top cap off. It is

hard to see but there is a small notch in the back of the cap where you can put the

small screwdriver and begin to pry the cap off. The cap will move easily so if you to

apply too much pressure you are likely pushing on the wrong place.

4. Invert the flow meter and catch the ball as it falls out.

5. You can use tooth paste or plastic window polish to polish the inside using a small

bottle brush or a Q

-

tip.

6. Clean the ball and give it a few coats of wax.

7. If the o

-

rings are damaged or the unit has been leaking, install new o

-

rings using a

little silicone grease to ease assembly. These are standard o

-

rings and should be

available at most larger auto parts or bearing stores. Reassemble in reverse.

Содержание AQUIFER 360 EXPEDITION

Страница 2: ...2...

Страница 27: ...27 Wiring Diagram...

Страница 28: ...28 John Guest Super Speedfit Fittings...

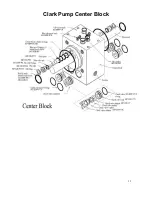

Страница 35: ...35 Clark Pump Center Block...

Страница 36: ...36 PL MTS 3 8X1 2S HP CYL SST HP CYL CCA SO HPP ECCB HP CYL EC HP CYL R HP CYL PT Clark Pump Cylinder Assembly...