11

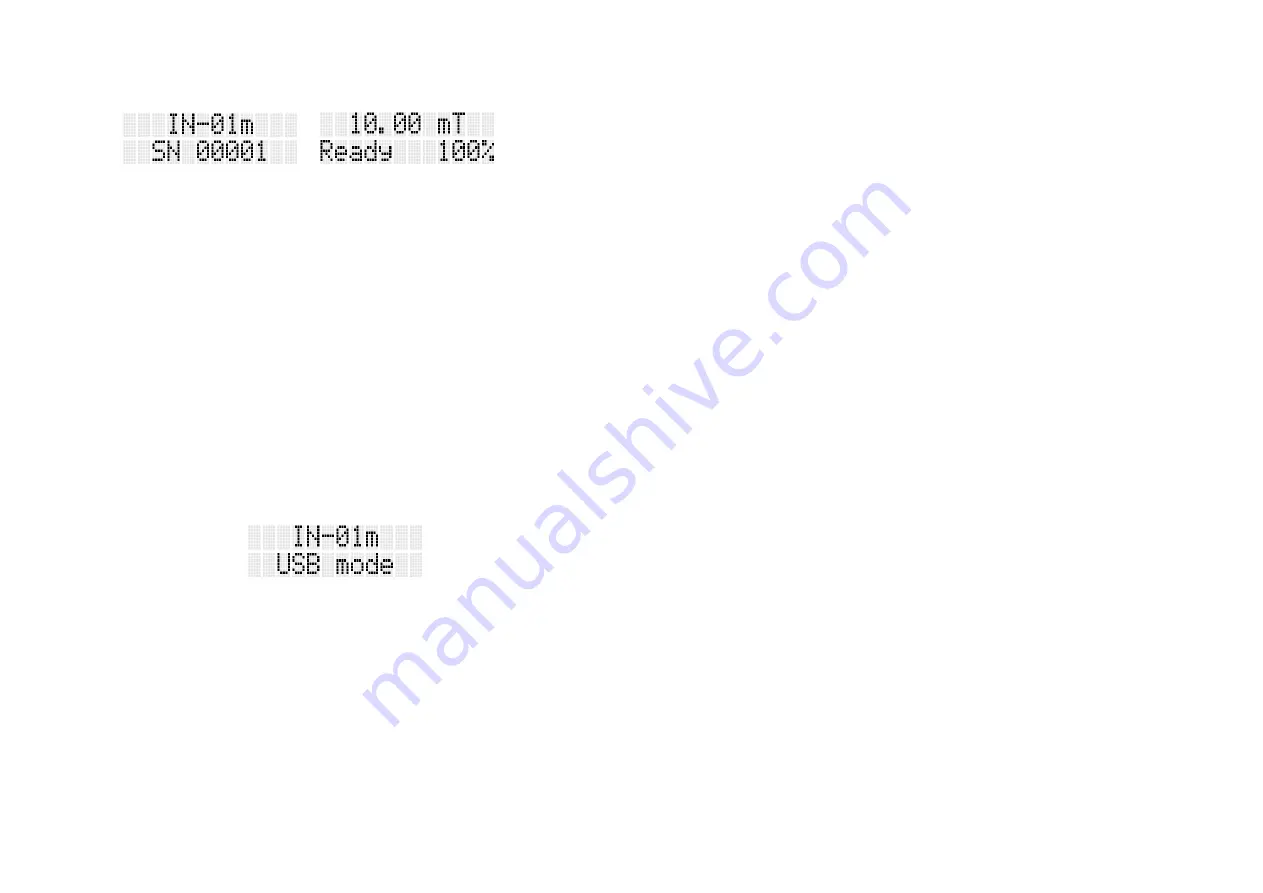

(a)

(b)

Fig.3.4. Displaying information on the IN-01m stress

indicator screen when the power is turned on (a) and after the

measurement mode is set (b)

3.4.3. Button 6 is used to turn on the stress indicator

screen backlight. When you turn on button 6, the screen is

illuminated with additional light to improve the display of

digital stress indicator readouts.

3.4.4. Button 7 is used to save measurements to the

electronic memory of the stress indicator. When the button 7 is

turned on or off, the current transmitter reading displayed on

the screen is recorded in the stress indicator memory.

3.4.5. When connecting a cable connected to the USB

port of a personal computer to the mini-USB 11 connector,

information about establishing a connection with the personal

computer appears on the stress indicator screen (Fig. 3.5).

Fig.3.5. Displaying information on the IN-01m stress

indicator screen when connected to a personal computer

Using of the IN-01m Connect software application pre-

installed on a personal computer, the measured information

from the stress indicator's electronic memory is transmitted

over a cable and stored in the personal computer's memory.

3.4.6. Button 8 displays the current date and time of

stress indicator on the screen.

12

3.5. Magnetizing unit

3.5.1. The magnetizing unit of the stress indicator is

used for magnetizing the local metal section of a steel product

or metal structure with a constant magnetic field, the intensity

vector of which is directed perpendicular to the metal surface.

3.5.2. The magnetizing device is non-volatile, single-

pole, rod type. It uses permanent magnets made from rare earth

metals.

3.5.3. The pole of the magnetizing device is protected

by an overlay to ensure convenience in the process, the handle

of the magnetizing device is provided with a strap.

3.6. Sensor

3.6.1. The stress indicator sensor is designed to

measure the field strength of the residual magnetization of

metal over the surface of a local section of a steel product or

metal structure.

3.6.2. The sensor contains a precision integrated Hall

Effect sensor chip and a precision integrated temperature

sensor chip with an analog signal output, which are located in

a single housing.

3.6.3. The Hall sensor plane is located in the center of

the transducer housing parallel to the working surface at a

distance of 0.5 mm from it.

3.6.4. To measure the field strength of the residual

magnetization of the metal, the center of the working surface

of the stress indicator

sensor

is set in the middle of the residual

magnetized area of the metal.